In making nose cones for click pens and for fountain pen front sections, controlled drilling depth is important. Historically I've drilled a little, measured, and drilled a bit more. I finally have gotten around to installing a DRO on the tail stock. You have two options, one that measures displacement or counts the rotation of the handle. I went the lower cost option of using the linear displacement type. The hardest part is making the forward clamp for the tailstock ram. So I came up with an install that doesn't require a clamp. I also wanted to be able to move the DRO from my metal lathe to my wood lathe painlessly. So I used some rare earth magnets to attach everything. Here are the materials I used and how I put it together. So far it works great. Total cost under $40.

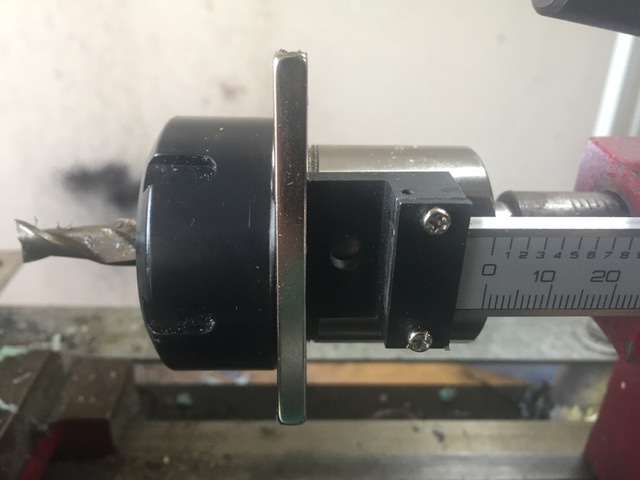

Here is how it looks installed.

here is how it is attached to the tailstock and the tooling.

I used the bracket that came with the DRO with one magnet to hold to the tailstock and another at a right angle that keeps it from sliding. I tried to use the magnets to stick directly to the DRO body but it increased the resistance by sticking the slide to the bar.

For the end of the bar I used another magnet to attach the end of the bar to the tooling in the tailstock. A ER32 chuck in this case but also my drill chuck works the same. To get it to work properly I had to position the magnets where the parts I wanted to attach were pulling away from the magnet. The magnets wouldn't hold if they were set up where they were position to try to stop something from sliding past.

It works quite well. It holds its zero when moving back and forth and during drilling steel with an end mill even when the lathe was vibrating and through some starting chatter. I was able to drill within 0.001" of what the DRO showed. Can't complain about that.

Removal is very simple. Care must be taken when handling the magnets though. If you aren't careful they will fly toward each other with enough force to break them. Separating them requires strong fingers and sliding them apart.

Let me know if you have any questions or suggestions to improve.

Danny

Here is how it looks installed.

here is how it is attached to the tailstock and the tooling.

I used the bracket that came with the DRO with one magnet to hold to the tailstock and another at a right angle that keeps it from sliding. I tried to use the magnets to stick directly to the DRO body but it increased the resistance by sticking the slide to the bar.

For the end of the bar I used another magnet to attach the end of the bar to the tooling in the tailstock. A ER32 chuck in this case but also my drill chuck works the same. To get it to work properly I had to position the magnets where the parts I wanted to attach were pulling away from the magnet. The magnets wouldn't hold if they were set up where they were position to try to stop something from sliding past.

It works quite well. It holds its zero when moving back and forth and during drilling steel with an end mill even when the lathe was vibrating and through some starting chatter. I was able to drill within 0.001" of what the DRO showed. Can't complain about that.

Removal is very simple. Care must be taken when handling the magnets though. If you aren't careful they will fly toward each other with enough force to break them. Separating them requires strong fingers and sliding them apart.

Let me know if you have any questions or suggestions to improve.

Danny

Last edited: