robutacion

Member

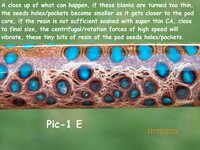

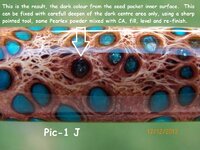

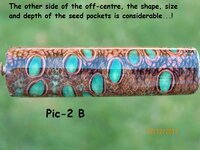

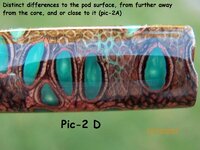

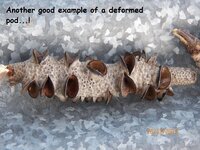

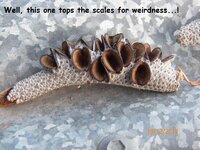

These dwarf Banksia pods, that I collect annually from my auto-mechanic property, also a source of many other timber species part of my collection, have been cast the same way since day one, I slice the long enough pods (full pen blank length or close enough) into 4 quarters and then cast them with all sorts of resin colours.

*

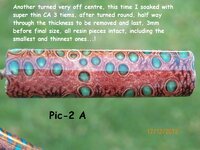

The pods were always cast raw as they are one of the best materials I used for casting that adheres to the PR (Polyester) resin, better than anything else I used so far, in the pod category so, they stay solid all the way through work/turning/drilling, etc.

The last time I made Resifills with these pods, I used all the long pods I had in stock, they were all sliced into 4 quarters, many were cast but, a fair number is still waiting for their turn. The last batch, I made 13 different colours, and a good number of each, and while they were selling quite OK, not so much lately, for whatever the reason.

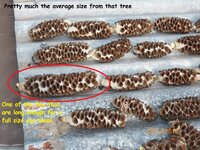

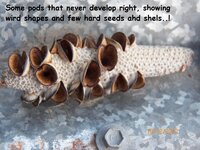

I was sorting a few boxes a few days ago and I come up with a box full of these pods that aren't long enough for a full length blank, the very ones I have been putting aside for one day to think what I could do with them, as these as the average size that small tree produces, 70% won't have enough length for a full blank. Well that day has come, and I set up to cut them into 2 major sizes, these are what I consider to be the best yield from their natural size so, the smallest ones were cut and 2" 1/2+(65mm) and the next size at 3" 1/4 - (81mm) approx.

What makes the major difference in between these new blanks and the old ones is that, with the new ones, each pod can only produce one blank (short) and I cut the edges/sides to keep the pod core at 21mm square.

*

I wanted to created a symmetric blank with these pods so that when turned into a pen barrel, it looks identical all around so, I had to sacrifice one pod per blank, instead of creating 4 blanks with one pod.

I cut today all the pods I had, not a huge amount but enough to make a few dozens of pens, I should have some ready or almost ready to pick-up from the tree from this year growth, I hope that I had a bag full, will see...!

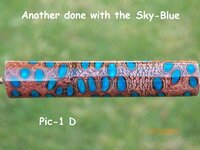

I cast 2 molds last night (12 shorts per mold) of both sizes, the shortest are Sky-Blue and the longest are Spring Green, those are the samples that I done on the pics, for you people to have a look.

I like the Sky-Blue the best, and tonight I put another 3 molds in the pressure pot, Sky-Blue (long ones), Pearlex Duo Green-Yellow and some other colour that don't remember its name...!

I should have enough to make another 4 or 5 molds, maybe tomorrow or so and get them all done in one go...!

I like to put my Resifills a side to bleed and rest for 4 weeks some even more and some a lot less, such as the case with these ones so, if is any interest for some of these among IAP members, I will put an add, just for them...!

I'm not yet sure of prices, as I use 1 pod per blank (short) so, will see...!:wink:

What do you reckon...????

Cheers

George

*

The pods were always cast raw as they are one of the best materials I used for casting that adheres to the PR (Polyester) resin, better than anything else I used so far, in the pod category so, they stay solid all the way through work/turning/drilling, etc.

The last time I made Resifills with these pods, I used all the long pods I had in stock, they were all sliced into 4 quarters, many were cast but, a fair number is still waiting for their turn. The last batch, I made 13 different colours, and a good number of each, and while they were selling quite OK, not so much lately, for whatever the reason.

I was sorting a few boxes a few days ago and I come up with a box full of these pods that aren't long enough for a full length blank, the very ones I have been putting aside for one day to think what I could do with them, as these as the average size that small tree produces, 70% won't have enough length for a full blank. Well that day has come, and I set up to cut them into 2 major sizes, these are what I consider to be the best yield from their natural size so, the smallest ones were cut and 2" 1/2+(65mm) and the next size at 3" 1/4 - (81mm) approx.

What makes the major difference in between these new blanks and the old ones is that, with the new ones, each pod can only produce one blank (short) and I cut the edges/sides to keep the pod core at 21mm square.

*

I wanted to created a symmetric blank with these pods so that when turned into a pen barrel, it looks identical all around so, I had to sacrifice one pod per blank, instead of creating 4 blanks with one pod.

I cut today all the pods I had, not a huge amount but enough to make a few dozens of pens, I should have some ready or almost ready to pick-up from the tree from this year growth, I hope that I had a bag full, will see...!

I cast 2 molds last night (12 shorts per mold) of both sizes, the shortest are Sky-Blue and the longest are Spring Green, those are the samples that I done on the pics, for you people to have a look.

I like the Sky-Blue the best, and tonight I put another 3 molds in the pressure pot, Sky-Blue (long ones), Pearlex Duo Green-Yellow and some other colour that don't remember its name...!

I should have enough to make another 4 or 5 molds, maybe tomorrow or so and get them all done in one go...!

I like to put my Resifills a side to bleed and rest for 4 weeks some even more and some a lot less, such as the case with these ones so, if is any interest for some of these among IAP members, I will put an add, just for them...!

I'm not yet sure of prices, as I use 1 pod per blank (short) so, will see...!:wink:

What do you reckon...????

Cheers

George