JD Combs Sr

Member

[FONT=&]I have a couple routers, a newer Bosch mounted in a table and an old(70s vintage) Craftsman. The Craftsman is my go-to for manual routing of items too big for the table. It did not have any sort of dust collection connection on it and I wanted to use it as a surface planner using a sled and rail arrangement but didn't like the idea of all the dust and chips flying all over the shop. [/FONT]

Here is the solution I came up with.

[FONT=&]

[FONT=&]

I started with two pieces of a 2x2 Holly tree spindle blank about 6" long. The second piece is a backup and is actually more as a counter balance on the faceplate to prevent vibration then a spare but…

[/FONT] [FONT=&]

[FONT=&]

After a couple or three iterations of turning and fitting I got the piece to fit into one of the side windows at the bottom of the router.

[/FONT][FONT=&] [/FONT]

[/FONT] [FONT=&]

[FONT=&]

Once fitted I found that it wasn't quite long enough for its intended purpose so I had to add a little to an end. I stepped(rabbeted) both pieces and then drilled and glued in ¼" dowels through the steps to reinforce the joint.[/FONT]

[FONT=&]

[FONT=&]

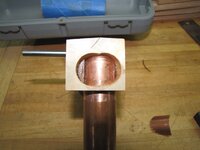

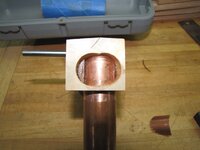

Using a 1" Forstner bit I drilled two side beside overlapping holes from the long end through to the center. I then use and 1-1/8" F-Bit to drill an opening on top to allow installation of a piece of 1.125" copper pipe. Before gluing in the copper pipe I cut the side out of it to allow air flow from the block through the pipe.[/FONT][FONT=&]

Previously to using the Forstner bits I clamped the block in place and use the routers edge guide mounting holes(shown in later pics) to locate a ¼" drill bit and drilled a hole through the block where I glued in a ¼" piece of SS drill rod as a locating/guide pin.[/FONT]

[FONT=&]

[FONT=&]

Here the pipe has been glued in with CA(super-glue) and the sides of it sealed. [/FONT]

(More in next post)

Here is the solution I came up with.

[FONT=&]

[FONT=&]I started with two pieces of a 2x2 Holly tree spindle blank about 6" long. The second piece is a backup and is actually more as a counter balance on the faceplate to prevent vibration then a spare but…

[/FONT]

[FONT=&]

[FONT=&]After a couple or three iterations of turning and fitting I got the piece to fit into one of the side windows at the bottom of the router.

[/FONT][FONT=&]

[/FONT]

[/FONT] [FONT=&]

[FONT=&]Once fitted I found that it wasn't quite long enough for its intended purpose so I had to add a little to an end. I stepped(rabbeted) both pieces and then drilled and glued in ¼" dowels through the steps to reinforce the joint.[/FONT]

[FONT=&]

[FONT=&]Using a 1" Forstner bit I drilled two side beside overlapping holes from the long end through to the center. I then use and 1-1/8" F-Bit to drill an opening on top to allow installation of a piece of 1.125" copper pipe. Before gluing in the copper pipe I cut the side out of it to allow air flow from the block through the pipe.[/FONT][FONT=&]

Previously to using the Forstner bits I clamped the block in place and use the routers edge guide mounting holes(shown in later pics) to locate a ¼" drill bit and drilled a hole through the block where I glued in a ¼" piece of SS drill rod as a locating/guide pin.[/FONT]

[FONT=&]

[FONT=&]Here the pipe has been glued in with CA(super-glue) and the sides of it sealed. [/FONT]

(More in next post)