There are 2, 3, 4 & 6 jaw chucks for metal lathes, that come in scroll and independent flavours and, as I just found out when looking, both independent & scroll in the same chuck. There are also many special chucks for special work holding too. The scope of chucks for metal lathes is staggering and makes the choices we have for wood lathes seem pitiful.

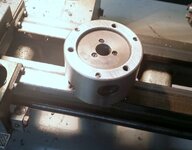

My metal lathe came with the standard faceplate, a 3 jaw scroll and a 4 jaw independent chucks. I've added a 4 jaw scroll and a 5C collet chuck to the mix and if I ever have the need I'll add a 6 jaw chuck.

The standard 3 jaw scroll is for quick clamping of round objects but the concentricity and consistency is limited by the quality of chuck. 4 and 6 jaw chucks do the same with the 4 jaw having the ability of also holding square material. The 6 jaw is meant for thin wall stock to reduce deformation.

Indépendant jaw chucks are meant to either centre stock more accurately, to hold odd shapes and hold parts off centre.

The chucks you buy beyond the ones that come with your lathe are dictated by what you are turning.