hanau

Member

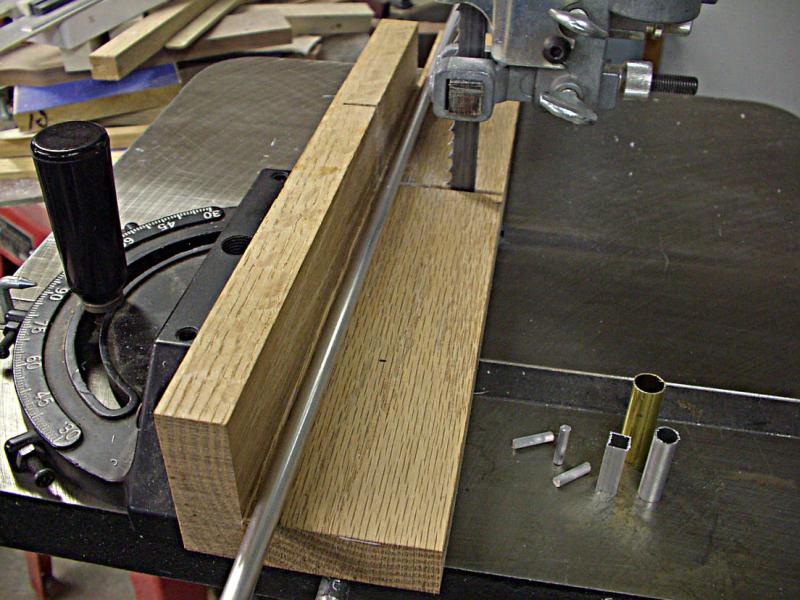

What is the best way to cut tubes?

I playing with casting and mainly using bolt action 3/8 tubes.

Last time I picked up some at the store they had a bulk pack think it was 10" long tubes but i would need to cut them to length.

I playing with casting and mainly using bolt action 3/8 tubes.

Last time I picked up some at the store they had a bulk pack think it was 10" long tubes but i would need to cut them to length.