robutacion

Member

Hi peoples,

Has been a very long time since I done any commissioned jobs of this nature however, I have a local (Adelaide) fellow that buys pen blanks from me and some round bowl blanks.

I remember clearly, the first time he come to visit my "lolly-shop" that he said that he only wanted soft woods to work with on the bowl blanks or anything bigger than a pen blank, I also remember him saying that, he hates turning hard stuff that brakes apart easily such as many burls and that he have had some bad experience with it so, no more of that.

He also mention that he had some burl blanks that he wanted to have turned into something nice as they cost him a bunch but, he wasn't going to touch them. I remember to say for him to bring them in one day, I would have a look...!

This was probably 7 or 8 months ago, when recently (few weeks back), I got a call from this person, asking if I was home as he was coming my way the next day. I told him that I would be at our wood storage paddock cutting some grass, not far from home, a place he has been before so, he would drop by, sometime middle morning the following day...!

I saw him coming with one of his 2 teenager sons, stop his van near where I was with my ride-on mower and I had a look what he had for me to work with.

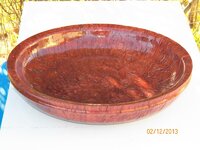

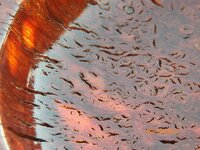

Fine burl specimens purchased from some wood shop or wood-show (never asked...!) and he asked me if I could make 3 nice pieces out of them. The biggest one the Australian Jarrah burl at 16",

he wanted it done as a fruit bowl and be done first, as it was going to be a Christmas present for his wife, the other 2, one a Salmon Gum burl (bowl blanks shape)

he wanted it done as a fruit bowl and be done first, as it was going to be a Christmas present for his wife, the other 2, one a Salmon Gum burl (bowl blanks shape)

and the other a full York Gum burl,

and the other a full York Gum burl,

I'm not 100% sure if they are going to be presents/gifts or he is going to keep them for himself.

I'm not 100% sure if they are going to be presents/gifts or he is going to keep them for himself.

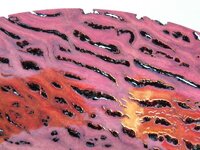

The 2 burls in a normal bowl blank shape, would be some sort of platters while the third burl, he only mentioned to me that, he wanted as much natural outer skin/surface as possible and that, he though that he would put 3 legs into it to stand it up.

This is all I was given as designs and I was fine with it, it gave me the freedom to work them as if they were mine. The only thing that I did do different was, the one with legs, I had to make 4 legs for it from the chunk of wood I manage to get from the burl centre, without having a proper hollower, sure I broke my made long diamond shape partition tool, just as I was finishing so, that allowed me to get a shallow cone shape from where I made the 4 legs from.

One of the problems was that, the piece is heavy and the wood of these burls is full of crystal veins that can make the wood very weak and fragile, so, after shaping the legs, they had to be fully soaked with thin and medium CA's to make the whole thing as a solid piece of wood.

After I cut a recess for the chuck and trim what was going to be the base of the piece, I realise that, 3 legs weren't an option due to the shape of the burl as the unbalanced mass of the whole thing so, the 4 legs would be a better option, I believe.

As for the final leg shape and positioning, there were too many options possible however, I could only use one so, considering what I was working with and its possible use, this was what I come up with...!

I got them all done, the 4 legs piece was my last one, that I finished Sunday night so, I'm going to let him know that he can come trough and pick them up, being very careful for another week and a half as the varnish takes 14 days to fully cure, but able to be handled within 24 hours.

I will put the final results pics on here very soon, they are all done but I don't want to have them all in this first post so, be patient, you will see them...!

One of the reasons for having them all done by the last weekend, apart from the time that the varnish takes to cure properly, is the fact that, yesterday I had to spend a few hours in hospital for a pre-admission tests for a surgery that I will have tomorrow (Wednesday 4/12) about lunch time and I'm told that I won't be able to walk around and do much for 1 week or so, I don't like to take unnecessary risks so, I felt that giving priority to this commissioned job, was the correct thing to do so, I haven't done much on IAP lately, in fact, the whole month of November so, with this extra computer time (I hope), I should be able go get some more "stuff" going this month...!

Cheers

George

Has been a very long time since I done any commissioned jobs of this nature however, I have a local (Adelaide) fellow that buys pen blanks from me and some round bowl blanks.

I remember clearly, the first time he come to visit my "lolly-shop" that he said that he only wanted soft woods to work with on the bowl blanks or anything bigger than a pen blank, I also remember him saying that, he hates turning hard stuff that brakes apart easily such as many burls and that he have had some bad experience with it so, no more of that.

He also mention that he had some burl blanks that he wanted to have turned into something nice as they cost him a bunch but, he wasn't going to touch them. I remember to say for him to bring them in one day, I would have a look...!

This was probably 7 or 8 months ago, when recently (few weeks back), I got a call from this person, asking if I was home as he was coming my way the next day. I told him that I would be at our wood storage paddock cutting some grass, not far from home, a place he has been before so, he would drop by, sometime middle morning the following day...!

I saw him coming with one of his 2 teenager sons, stop his van near where I was with my ride-on mower and I had a look what he had for me to work with.

Fine burl specimens purchased from some wood shop or wood-show (never asked...!) and he asked me if I could make 3 nice pieces out of them. The biggest one the Australian Jarrah burl at 16",

he wanted it done as a fruit bowl and be done first, as it was going to be a Christmas present for his wife, the other 2, one a Salmon Gum burl (bowl blanks shape)

he wanted it done as a fruit bowl and be done first, as it was going to be a Christmas present for his wife, the other 2, one a Salmon Gum burl (bowl blanks shape)

and the other a full York Gum burl,

and the other a full York Gum burl,

I'm not 100% sure if they are going to be presents/gifts or he is going to keep them for himself.

I'm not 100% sure if they are going to be presents/gifts or he is going to keep them for himself.The 2 burls in a normal bowl blank shape, would be some sort of platters while the third burl, he only mentioned to me that, he wanted as much natural outer skin/surface as possible and that, he though that he would put 3 legs into it to stand it up.

This is all I was given as designs and I was fine with it, it gave me the freedom to work them as if they were mine. The only thing that I did do different was, the one with legs, I had to make 4 legs for it from the chunk of wood I manage to get from the burl centre, without having a proper hollower, sure I broke my made long diamond shape partition tool, just as I was finishing so, that allowed me to get a shallow cone shape from where I made the 4 legs from.

One of the problems was that, the piece is heavy and the wood of these burls is full of crystal veins that can make the wood very weak and fragile, so, after shaping the legs, they had to be fully soaked with thin and medium CA's to make the whole thing as a solid piece of wood.

After I cut a recess for the chuck and trim what was going to be the base of the piece, I realise that, 3 legs weren't an option due to the shape of the burl as the unbalanced mass of the whole thing so, the 4 legs would be a better option, I believe.

As for the final leg shape and positioning, there were too many options possible however, I could only use one so, considering what I was working with and its possible use, this was what I come up with...!

I got them all done, the 4 legs piece was my last one, that I finished Sunday night so, I'm going to let him know that he can come trough and pick them up, being very careful for another week and a half as the varnish takes 14 days to fully cure, but able to be handled within 24 hours.

I will put the final results pics on here very soon, they are all done but I don't want to have them all in this first post so, be patient, you will see them...!

One of the reasons for having them all done by the last weekend, apart from the time that the varnish takes to cure properly, is the fact that, yesterday I had to spend a few hours in hospital for a pre-admission tests for a surgery that I will have tomorrow (Wednesday 4/12) about lunch time and I'm told that I won't be able to walk around and do much for 1 week or so, I don't like to take unnecessary risks so, I felt that giving priority to this commissioned job, was the correct thing to do so, I haven't done much on IAP lately, in fact, the whole month of November so, with this extra computer time (I hope), I should be able go get some more "stuff" going this month...!

Cheers

George

Last edited: