I can't get Alumilite here and am not sure what it is that I am getting - in English terms. I have tried fiberglass (FRP) in which I add a few drops; I have tried a clear base that uses 2 parts one mix to 1 part other; and I have one brand that used 1 to 1 mix.

The 1 to 1 mix cures in around 5 minutes. The 2 to 1 mix takes 24 hours on average.

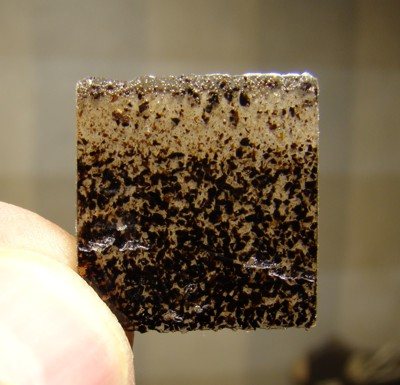

My process: I use Gadgets moulds and fill mine with coffee beans and on one occasion very coarse ground beans. (I actually over fill just a tad. Next I make sure the mix is around 90 degrees (I microwave it for a few seconds - up to 10 seconds). This thins it out and accelerates the hardening action, but it makes it very thin - enough to get into the cracks and eliminates bubbles because the viscosity is so thin. The beans want to rise a small amount and I place a cut open quart milk carton - the waxed kind, and lay it on top and place a board on that and a weight on top of that. It keeps the beans and grounds down.

I was VERY surprised that the coarse grounds were penetrated so well and without bubbles. By the way, this preheating to about 90° has eliminated most all of the bubbles without using pressure.

I was TRYING to get bubbles for a special effect, didn't use pressure or vacuum - and all of a sudden I didn't get ANY! The heating process eliminated the bubbles by making the viscosity such that the bubbles floated out quickly. I don't think this will work on the 5 minute stuff, AND I don't think it will work if it is heated any higher.

I have been experimenting just to see what would happen and to get some experience. I might post some photos tomorrow (Tuesday here) If I get the time.