Chasboy1

Member

Hi folks, I haven't been around for awhile, in good weather its car show/cruise season and once "the brine" is on our roads, my Corvette stays home.

I decided that rather than use certain shortcuts for rounding a blank, I'm going to use 'big boy' techniques and use my lathe chisels to do the job. I have a square and round tip carbide tipped tool from John at NCWoodturning tools. They are worth the money and since I work primarily with acrylics I like the fact that they don't dull easily.

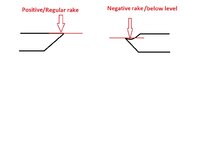

My question is I've seen info regarding negative rake carbide tips. I was having a problem with frequent chipouts and for the heck of it tried the tool upside down, thinking I was giving it a sort of negative rake. I must say the cut was smooth but did not cut very fast. Was I fooling myself in this regard?

Another question is tool angle as it approaches the work. I heard that it was different for carbide but I don't remember what it was. The carbide tool shaft is much thicker than my old ones and the cutting tip is at the top, which adds to my confusion.

That's about all I can remember for now.

thanks everyone1

I decided that rather than use certain shortcuts for rounding a blank, I'm going to use 'big boy' techniques and use my lathe chisels to do the job. I have a square and round tip carbide tipped tool from John at NCWoodturning tools. They are worth the money and since I work primarily with acrylics I like the fact that they don't dull easily.

My question is I've seen info regarding negative rake carbide tips. I was having a problem with frequent chipouts and for the heck of it tried the tool upside down, thinking I was giving it a sort of negative rake. I must say the cut was smooth but did not cut very fast. Was I fooling myself in this regard?

Another question is tool angle as it approaches the work. I heard that it was different for carbide but I don't remember what it was. The carbide tool shaft is much thicker than my old ones and the cutting tip is at the top, which adds to my confusion.

That's about all I can remember for now.

thanks everyone1