Penultimate

Member

Greetings

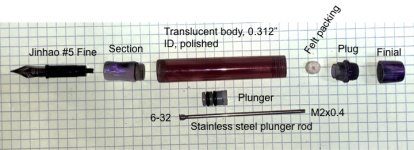

i posted a bulk filler fountain pen in SOYP and thought this would be a good place to show the inner workings.

The body is translucent cast acrylic, section, seal and finial are Alumilite, plunger is acetal. Capped length is 4.9"(124.5mm), uncapped length is 4.55" (115.6mm), largest diameter is 0.505" (12.87mm), Cap threads are 12-32, section to body threads are 3/8-24. I designed the section a little too short at 0.63", it's about the same size as a Parker Vacumatic.

The body is drilled out, reamed and polished on the lathe. The reamer leaves a nice surface so polishing with tripoli and white diamond give a nice finish. I use rotary tool bobs, the same size as the bore, eliminates the risk of making the ID out of round. That would mess up the vacuum.

The plunger has two external o-rings, I use Apple Rubber Products o-ring calculator to help with sizing. The plunger has a thru bore with a 6-32 thread on one half and a pocket for an internal ring that seals the plunger shaft on the other side. There are two castellations on the end that mate to the seal. I took me 5 tries, and this was the simplest. (Occam's razor corollary?)

The stainless steel plunger shaft goes thru the plunger. There is a 6-32 set screw on the end that screws into the plunger that allows you to push down then draw ink up, then unscrew the shaft, push it down to store and leave the plunger at the seal end of the pen.I made the 6-32 set screw from Aluminum with an M2 internal thread. It took me a couple tries.

The seal has an slightly oversized 2mm thru bore and a 1/4" bore to hold felt packing. I'm not sure I need it but I saw it in a patent. The part that fits into the pen body also has castellations on it to hold the plunger from turning when screwing or unscrewing the plunger shaft.

The finial is tapped M2 to hold the plunger rod and 3/8-24 to thread onto the seal.

The Jinhao nib has a thread very close to a 1/4-36 so I chased the thread and it worked well with the section. Nothing special about the section except the o-ring.

Thanks for lookin'

Questions or comments appreciated

Mike

i posted a bulk filler fountain pen in SOYP and thought this would be a good place to show the inner workings.

The body is translucent cast acrylic, section, seal and finial are Alumilite, plunger is acetal. Capped length is 4.9"(124.5mm), uncapped length is 4.55" (115.6mm), largest diameter is 0.505" (12.87mm), Cap threads are 12-32, section to body threads are 3/8-24. I designed the section a little too short at 0.63", it's about the same size as a Parker Vacumatic.

The body is drilled out, reamed and polished on the lathe. The reamer leaves a nice surface so polishing with tripoli and white diamond give a nice finish. I use rotary tool bobs, the same size as the bore, eliminates the risk of making the ID out of round. That would mess up the vacuum.

The plunger has two external o-rings, I use Apple Rubber Products o-ring calculator to help with sizing. The plunger has a thru bore with a 6-32 thread on one half and a pocket for an internal ring that seals the plunger shaft on the other side. There are two castellations on the end that mate to the seal. I took me 5 tries, and this was the simplest. (Occam's razor corollary?)

The stainless steel plunger shaft goes thru the plunger. There is a 6-32 set screw on the end that screws into the plunger that allows you to push down then draw ink up, then unscrew the shaft, push it down to store and leave the plunger at the seal end of the pen.I made the 6-32 set screw from Aluminum with an M2 internal thread. It took me a couple tries.

The seal has an slightly oversized 2mm thru bore and a 1/4" bore to hold felt packing. I'm not sure I need it but I saw it in a patent. The part that fits into the pen body also has castellations on it to hold the plunger from turning when screwing or unscrewing the plunger shaft.

The finial is tapped M2 to hold the plunger rod and 3/8-24 to thread onto the seal.

The Jinhao nib has a thread very close to a 1/4-36 so I chased the thread and it worked well with the section. Nothing special about the section except the o-ring.

Thanks for lookin'

Questions or comments appreciated

Mike