hooked

Member

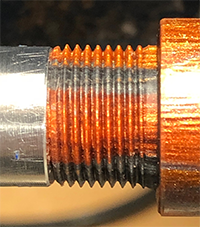

Thanks to everyone's advice, my second pen came out much better. Picture below. My threads are looking great now. I have a tenon issue I was hoping to throw out there and see if anyone has any ideas of what I may be doing wrong. I am using single start tap/die here—M11x.75, M14x1, and Jowo #6. I am using measurements from a guide that came with the taps and dies.

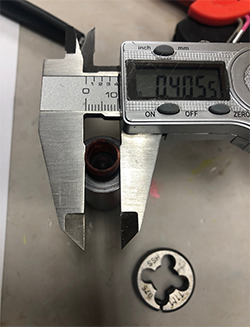

My body tenon seems right, and it fits great on the mandrel. I cut my tenon to .545. It measures .545 (top of threads) after I put threads on it. Every cap fit has been great. Internally, I am cutting with a Y bit (.404) to accept the section tenon.

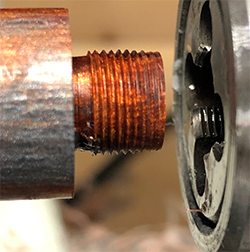

The section tenon I turned to .425 as instructed, but my fit was very loose there. On my latest (5th) attempt, I made certain that my tenon was oversized to .430 on both ends to be sure. I run my die through with the lettering out, and then I rerun it with the die reversed.

I notice that after I cut with the die, the end of my tenon is measuring .389 at the end with flat threads at the start and goes up to .405 (top of threads) at the end. My last thread seems to be the only one catching on to the tenon. After five attempts, I have noticed that this is happening no matter what size I make my tenon. I think that I am doing something incorrectly. Should my tenon reduce from .430 to .389-.405 when I cut with the M11 die? I don't feel any additional resistance when using the die. Any advice?

Here is pen #2. Again, I am happy with this one except for the fact that I have teflon tape on the threads making a tight fit into the body.

My body tenon seems right, and it fits great on the mandrel. I cut my tenon to .545. It measures .545 (top of threads) after I put threads on it. Every cap fit has been great. Internally, I am cutting with a Y bit (.404) to accept the section tenon.

The section tenon I turned to .425 as instructed, but my fit was very loose there. On my latest (5th) attempt, I made certain that my tenon was oversized to .430 on both ends to be sure. I run my die through with the lettering out, and then I rerun it with the die reversed.

I notice that after I cut with the die, the end of my tenon is measuring .389 at the end with flat threads at the start and goes up to .405 (top of threads) at the end. My last thread seems to be the only one catching on to the tenon. After five attempts, I have noticed that this is happening no matter what size I make my tenon. I think that I am doing something incorrectly. Should my tenon reduce from .430 to .389-.405 when I cut with the M11 die? I don't feel any additional resistance when using the die. Any advice?

Here is pen #2. Again, I am happy with this one except for the fact that I have teflon tape on the threads making a tight fit into the body.