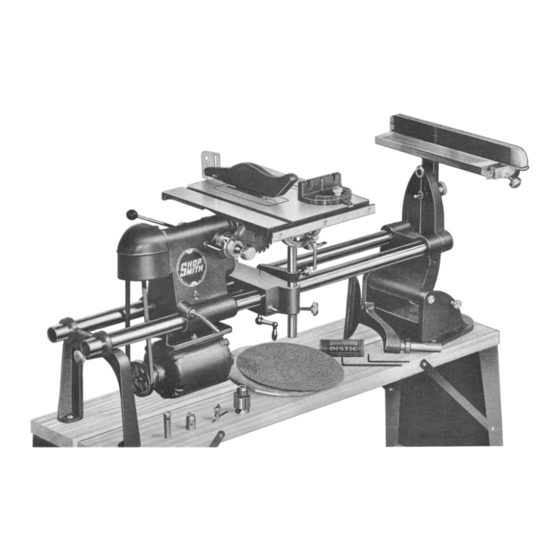

Hi Brad, I have a Shopsmith Mark 5, although I do not turn pens on it. I would suggest a slightly different system. I would get a spindle adapter to convert the 5/8" spindle of your Shopsmith to a more standard 1", 8 TPI spindle. Then I would get this mandrel from PSI:

Mandrel Set fits 1 x 8tpi HeadstockThread on 1 x 8tpi screw on. Includes long mandrel, knurled nut, seven Slimline Bushings (#PKM-BUSH3), 7mm drill bit. Compatible with all PSI bushings and kits. Our precision mandrel sets inlude lathe accesories necessary for making Slimline pen and pencil sets. Ma

www.pennstateind.com

I would also strongly suggest the mandrel saver as well (please verify that the tailstock on your Shopsmith is a #2 MT, mine is and yours probably is too as Shopsmith kept a lot of items standard as they developed new models, but you want to check to be sure.

Are you tired of bending your Mandrel and ruining the point on your live center? If so, then this fail-safe live center accessory is for you. Mandrels usually bend when you tighten the tailstock center point into the end indentation of your mandrel. This system solves that problem because your ma

www.pennstateind.com

The reason I suggest using the spindle adapter is someday you might get a midi lathe or a dedicated full size lathe, and if you get all your accessories (mandrels, chucks, etc) based on the non-standard 5/8 spindle on the Shopsmith, they will not be as useful on your new lathe as a 1" X 8TPI mounting scheme.

You can get the spindle adapter from PSI or ebay as I did:

Adapter From 5/8 compatible with Shopmith® headstock to 1 x 8tpi male thread. Convert your spindle so that you can use chucks with different thread sizes.

www.pennstateind.com

or

There is no internal thread. It's a smooth bore.

www.ebay.com

I really like using my Shopsmith's disc sander to sand down the corners on my acrylic blanks as it really cuts down on turning time and eliminates catching the corners, etc. if you are turning a square blank.

Also, if you are missing any accessories, check on eBay as you can get them usually at a much better price than from Shopsmith directly. Good luck, David