mmayo

Member

Other parts of this series: Part 2

I drill a lot of blanks and they need to all make it to a future sale. The drilled blanks will all become Diamond Knurl Ballpoint pens.

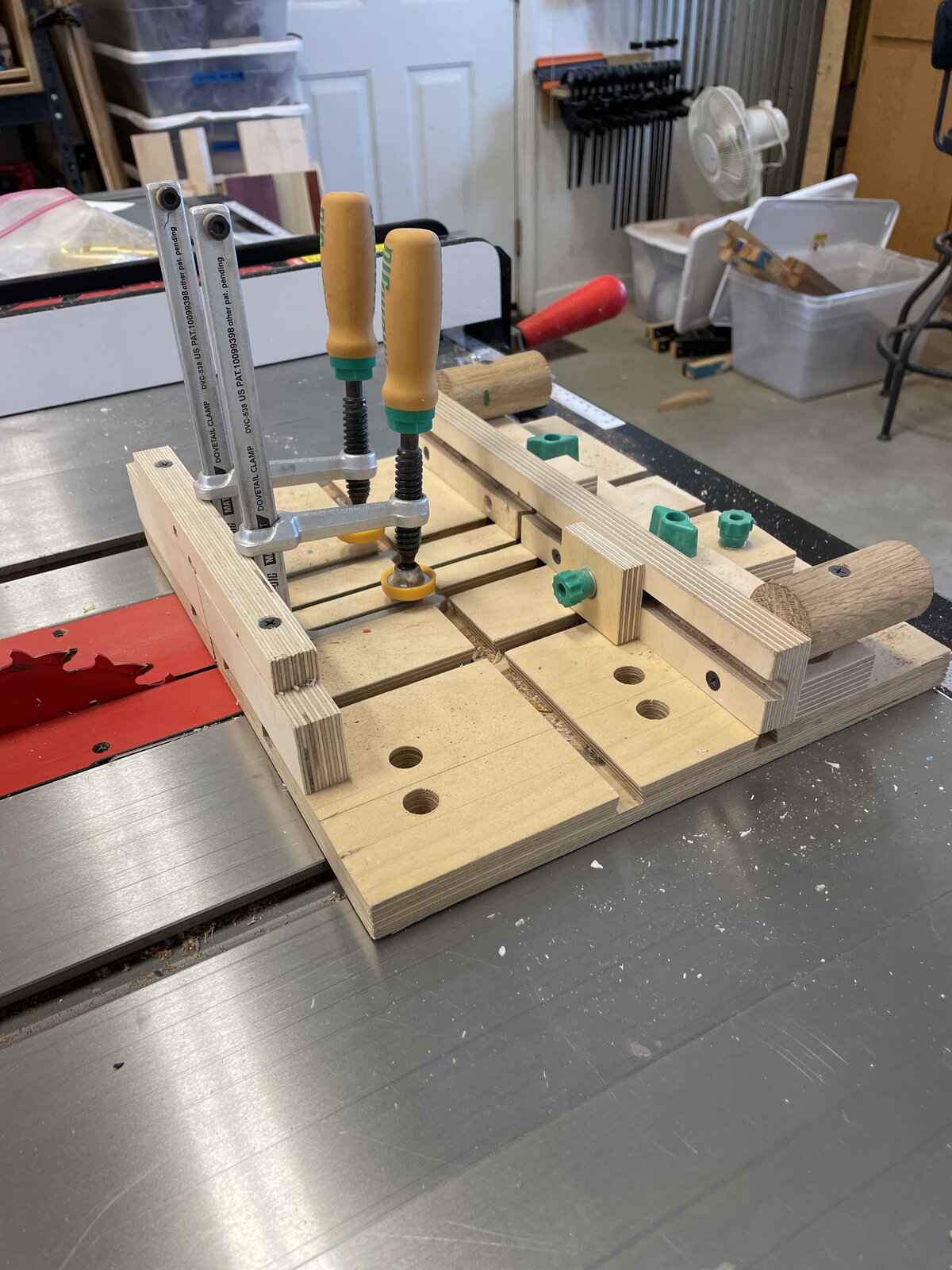

I start be cutting full size 3/4 square blanks to 5/8" square. This will greatly reduce your turning IF you can drill straight - the lathe makes it easy. I use a sled which employs Microjig clamps to cut the blanks to fit the tube.

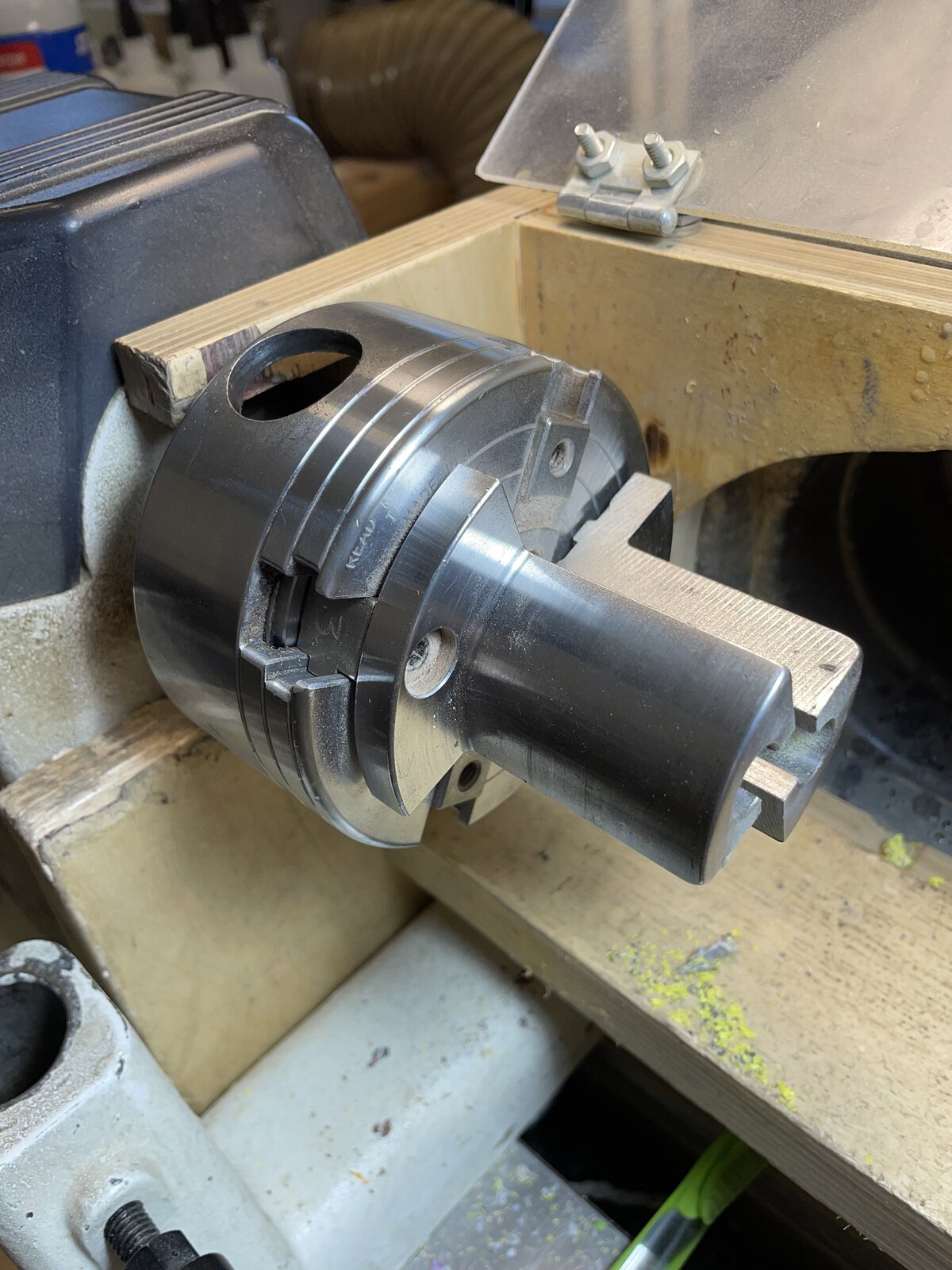

Once cut, I drill the blanks on my lathe. You need a chuck with pen jaws. This one has drilled hundreds perfectly and has hundreds left in the tank.

You also need a drill chuck to fit your tailstock. Mine works and was cheap.

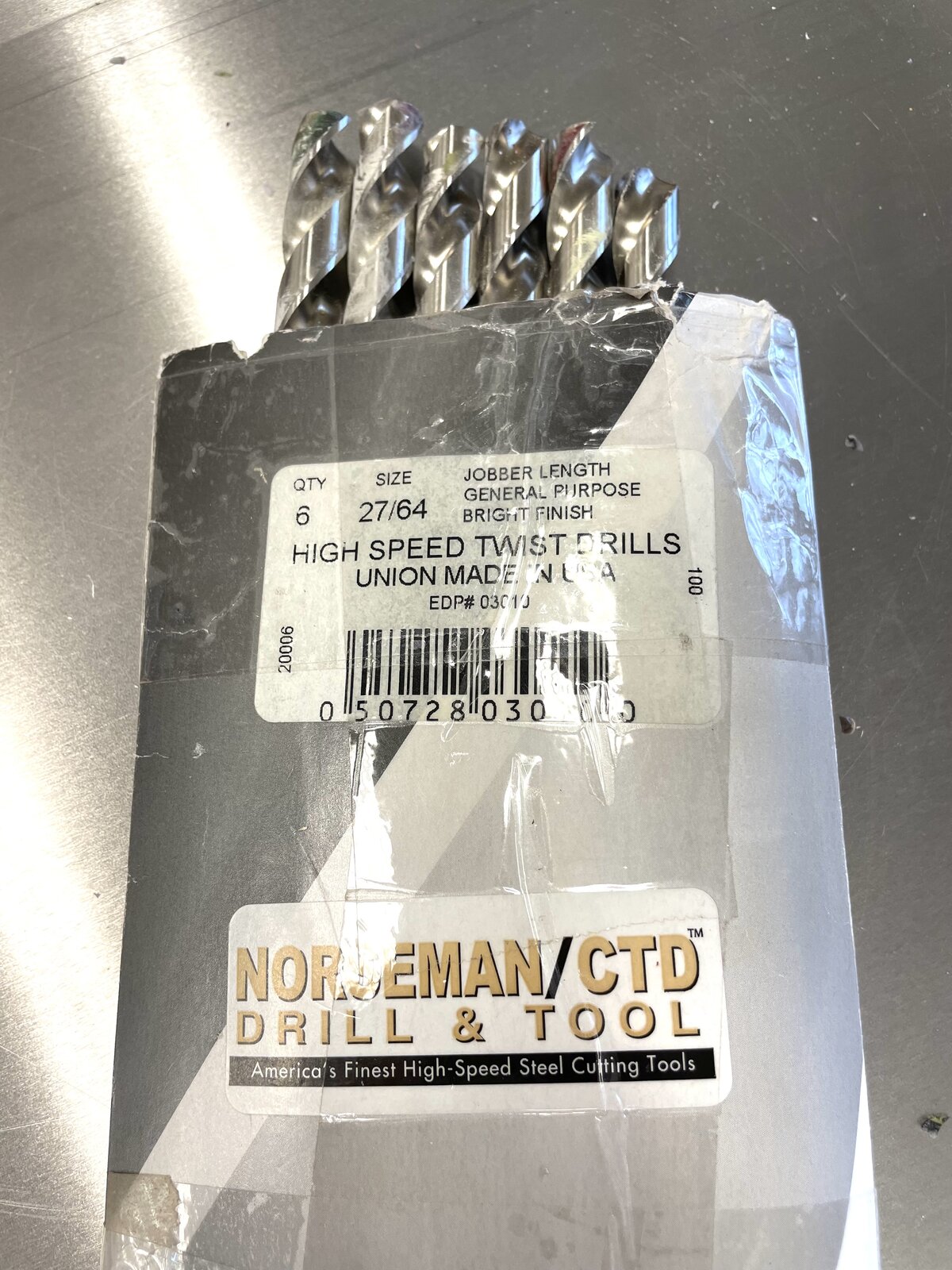

I STRONGLY suggest you upgrade to high quality drill bits by Norseman!!! The drill bits that come with kits or package deals are to be avoided. These rock!

I have six at present and carefully rotate them to use a cold or cool bit to drill each new blank. If you have one, have a cup of cold water to cool the bit after each blank. Shake off the water. S L O W D O W N when you drill especially when you enter and exit the blank. Clear chips each 1/2" or 1 cm (that means move the bit out of the blank and safely get rid of the ribbons or wood chips). There is a video to show how slow to advance in the photos below. (850 rpm).

Here are my results. These are acrylic acetate and Inlace acrylester. Be even slower with Inlace especially at the end.

Best of luck!

I drill a lot of blanks and they need to all make it to a future sale. The drilled blanks will all become Diamond Knurl Ballpoint pens.

I start be cutting full size 3/4 square blanks to 5/8" square. This will greatly reduce your turning IF you can drill straight - the lathe makes it easy. I use a sled which employs Microjig clamps to cut the blanks to fit the tube.

Once cut, I drill the blanks on my lathe. You need a chuck with pen jaws. This one has drilled hundreds perfectly and has hundreds left in the tank.

You also need a drill chuck to fit your tailstock. Mine works and was cheap.

I STRONGLY suggest you upgrade to high quality drill bits by Norseman!!! The drill bits that come with kits or package deals are to be avoided. These rock!

I have six at present and carefully rotate them to use a cold or cool bit to drill each new blank. If you have one, have a cup of cold water to cool the bit after each blank. Shake off the water. S L O W D O W N when you drill especially when you enter and exit the blank. Clear chips each 1/2" or 1 cm (that means move the bit out of the blank and safely get rid of the ribbons or wood chips). There is a video to show how slow to advance in the photos below. (850 rpm).

Here are my results. These are acrylic acetate and Inlace acrylester. Be even slower with Inlace especially at the end.

Best of luck!

Attachments

Last edited by a moderator: