FGarbrecht

Member

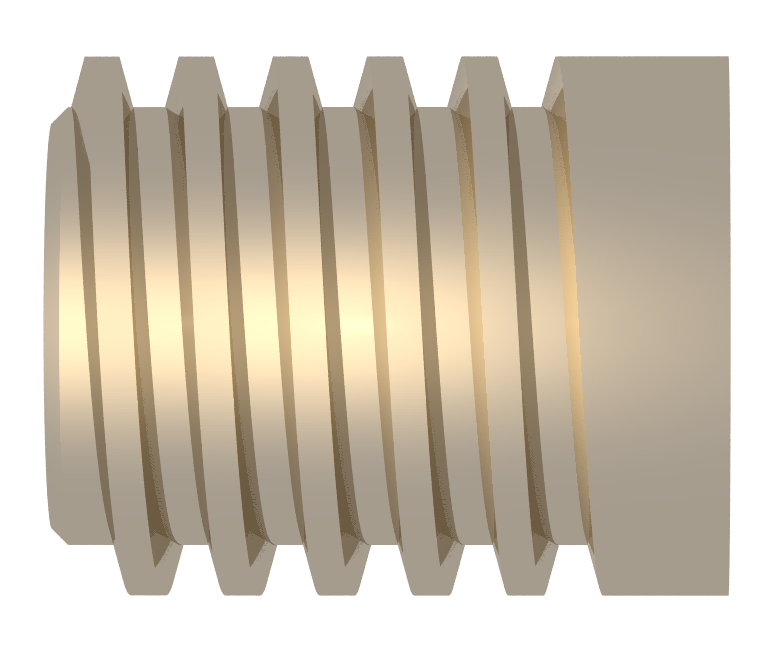

I'm building a wood threading machine (sort of like the one written up in the 'Resources' section) and I'm using an acme 3/4" x 10 tpi threaded rod (from Lowe's) connected to a spindle adapter (from PSI) connected to a collet chuck to hold the work and advance it into the cutting tool. The threaded rod I got isn't completely straight so there is an unacceptable amount of wobble (maybe 10 thou or so, just guessing but big enough to be clearly visible) at the collet. So I ordered a piece of 'precision acme threaded drive rod', thinking that would be straighter (this was from McMaster-Carr), but there's something about it that isn't working -- the spindle adapter won't thread onto the end, nor will it thread into the guide bushings I made. So I measure the precision rod and the thread pitch is correct (10 tpi) but the overall diameter is slightly more than .75 inches (whereas the cheap acme rod is slightly less than 0.75 inches. I assumed that since the expensive rod is sold as an acme thread that the thread geometry is the same, but I don't know enough about machining and threads to really know.

It seems like I have a couple options: 1) bang on the cheap rod with a hammer to see if I can straighten it enough to be functional and accurate 2) try to machine down the diameter of my precision rod on the metal lathe and see if the problem really is just that it is just slightly too large in overall diameter. 3) Go back to Lowe's or HD with a good straightedge and try to find a straight piece of threaded rod. Any bright ideas?

It seems like I have a couple options: 1) bang on the cheap rod with a hammer to see if I can straighten it enough to be functional and accurate 2) try to machine down the diameter of my precision rod on the metal lathe and see if the problem really is just that it is just slightly too large in overall diameter. 3) Go back to Lowe's or HD with a good straightedge and try to find a straight piece of threaded rod. Any bright ideas?