Mortalis

Member

I received my order of a Type II On/Off switch.

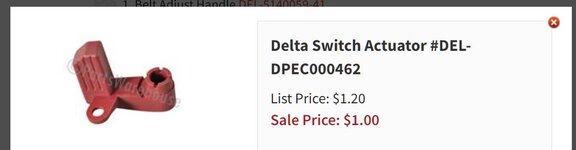

I need some info from the community of anyone that has a Type II 46-460. I would like to see how the On/Off switch is situated on the lathe. The Type I mounts relatively flush as far as the top of the body of the switch. The Type II has an arm that the switch paddle mounts to but this arm extends below the top surface of the body of the switch. this would appear to me that the On/Off switch on the Type II either sits near the edge of the control box or that there is an indentation in the control box that allows that arm to fit with the top of the switch flush with the control box cover.

I either need to modify the control box to allow the arm to clear the control box cover or I need to trim the arm so that it no longer extends down below the surface lf the control box. I would like to see how this is accomplished on the Type II lathe. I've tried to look at pictures of the Type II lathe but they are very ambiguous and do not specifically detail that portion of the lathe. If someone could post a couple pictures of their Type II lathe On/Off switch mount it would be very helpful.

Thanks,

Kevin

I need some info from the community of anyone that has a Type II 46-460. I would like to see how the On/Off switch is situated on the lathe. The Type I mounts relatively flush as far as the top of the body of the switch. The Type II has an arm that the switch paddle mounts to but this arm extends below the top surface of the body of the switch. this would appear to me that the On/Off switch on the Type II either sits near the edge of the control box or that there is an indentation in the control box that allows that arm to fit with the top of the switch flush with the control box cover.

I either need to modify the control box to allow the arm to clear the control box cover or I need to trim the arm so that it no longer extends down below the surface lf the control box. I would like to see how this is accomplished on the Type II lathe. I've tried to look at pictures of the Type II lathe but they are very ambiguous and do not specifically detail that portion of the lathe. If someone could post a couple pictures of their Type II lathe On/Off switch mount it would be very helpful.

Thanks,

Kevin