workinforwood

Member

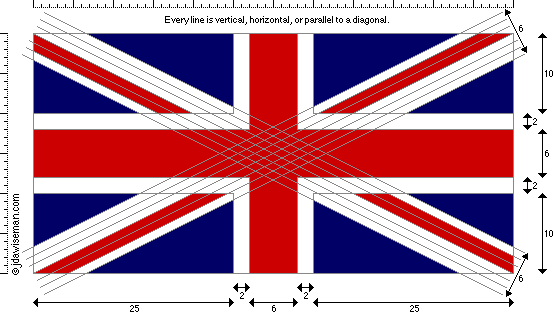

I have been working for hours attempting to replicate the Union Jack for my British and Australian friends. I always knew it's a real challenge because it is a precision double pour, but it turns out to be far more complicated than that! At a glance, the over all appearances of a USA flag vs a British flag, the USA seem more complicated. But the USA flag is packed full of repeatable images. You British people likely already know this but I and I imagine the majority of us non British flag countries don't realize that the Union Jack is not an x over a t. Ok..I do realize this...NOW, but I didn't until I started trying to program it and then came to realize it was all wrong and had to delete all my hard work. It's a very complicated design that is certainly boggling my mind a bit!