Well Happy New Year to everyone !!!

Since I didn't have plans to go out lastnight, my main plan was getting something done on this project. So here it is..of course keep in mind this is my first and I know nothing is perfect on it. But the end results, I am happy how it turned out. I will be giving it to a guy at work since he helped spark the idea. Tradionally Smoking pipes as I have read are usually made with Briar wood. But I woked with what I have....Bubinga.

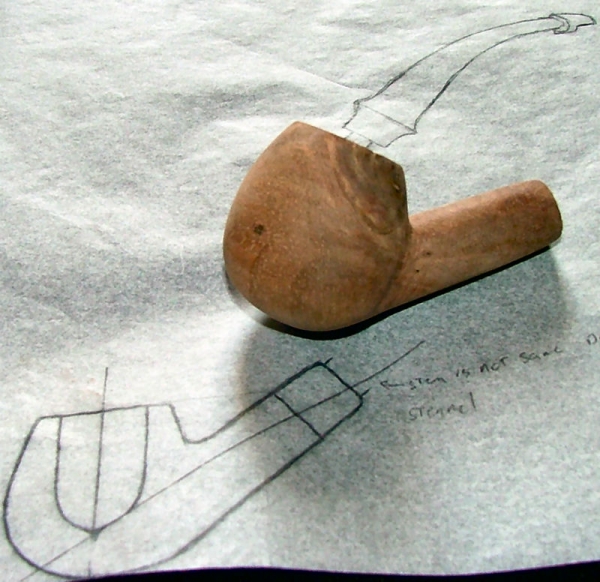

A couple posts back I showed the block and had just rounded it...Well here it continues to the finished item...

Stem shaped to design. I drilled a 3/16" bore through it, but found out I can go as small as 1/8" to 5/32"...

I had to make some tenon turning jig/pieces to turn it.

Stem finished with burned accent rings and a Hut fiction polish (brown)...

Bubinga block for the bowl/cup drilled on top with 7/8" forstener bit to depth of 5/8" down. Some pipes are known to go deep as 1.5"...On the side is a 3/8" bore for the tenon of the stem....

Checking tenon of stem...

As the same 3/16" bore of the stem, I continued on into the block where I drilled for the tenon, this is lined up just enough to open the chamber...

So onto the lathe work again...I figured how thick I wanted the brim and rounded the edge....and length down of 2"....

Decided to add 2 more burned ring accents and decided a design test.

So at this point I am happy with how its going so far. I decided to get the top sanded and finished to part it, then rechuck and turn and finish the bottom

So I didn't get pics of turning the bottom...But here is the results....

So....Now the question is, If I were to make some more, how much would one think a pipe like this may cost? I was thinking since I am beginning, $50.00 at least sounds reasonable for a crafted pipe. Let me know what you think.

Thanks for looking....GO DUCKS !!! hehe