IPD_Mr

Member

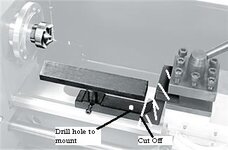

I purchased a tool rest from Micro-Lux that goes into the 101 holder on the QCTP. The concept is fine but there is no way to get it close enough to the stock. I was hoping that someone like Rick has a design for one that would allow you to get as close as you would on a wood lathe. If I could get the rest about 3" closer, I could all but do away with the wood lathe for my purposes. Any ideas out there? Here is what the product looks like, may some ideas can be gained from the photo.