juteck

Member

[FONT="]Stabilized/Dyed Pen Blank Review[/FONT]

[FONT="]Pen Blanks provided by: Constant Laubscher of www.lazerlinez.com [/FONT]

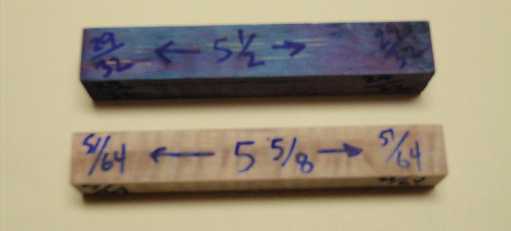

[FONT="]I received these blanks at the end of August, and started working them on September 19, 2009. Both blanks were greater than 3/4-inches square, at least 5-1/2 inches in length, surfaced on four sides, and straight with no warping, bowing, or twisting. The blue dyed blank in square form showed signs of blue and purple hues on all four sides. The natural blank was cut from two tone material, and showed promising fiddleback/tiger stripe figure. [/FONT]

[FONT="]For comparison purposes for this review discussion, I also turned a non-stabilized, non-dyed birdseye maple blank and a commercially stabilized dyed box elder burl blank using the same techniques (no photos of these comparison blanks though) .[/FONT]

[FONT="]All blanks were turned between centers using a spindle roughing gouge with little to no signs of tearout. After the blanks were fully round, the non-stabilized maple blank cut nice curls, whereas the stabilized blanks all cut short chips. The commercially stabilized blank appeared to be the hardest when turning, and Constant's stabilized blanks cut somewhere between the non-stabilized blank and commercially stabilized blank. [/FONT]

[FONT="]All blanks were dry sanded through 400-grit using Klingspor's gold paper, then dry sanded through 2000-grit using the grey automotive wet/dry paper. When sanding through 400-grit, more resin accumulated on Constant's blanks in comparison to the commercially stabilized blank, and more so with Constant's dyed blank compared to his natural blank. When sanding through the 600- to 2000-grit range, Constant's dyed blank left more color dust on the sandpaper, in comparison to the commercially stabilized blank which left a near-white dust. After sanding, Constant's blanks appeared to be similar to the commercially stabilized blank in shine, and were considerably better than the non-stabilized blank. [/FONT]

[FONT="]All blanks were polished with EEE and Shellawax. Constant's blanks polished as well as the commercially stabilized blank; although, the non-stabilized blank appeared to polish equally as well at this point. The blue/purple hues in Constant's dyed blank remained throughout this rough turning and polishing, with some grain lines that did not take the dye. A picture of Constant's rough-turned, sanded, and polished blanks are shown below:[/FONT]

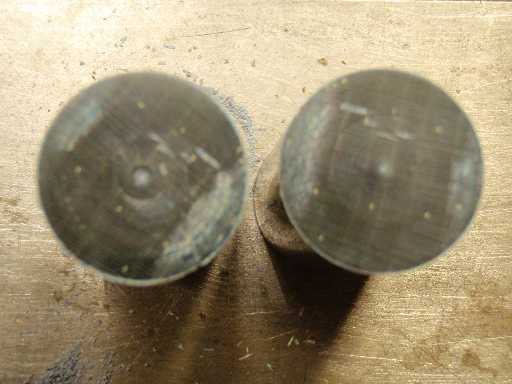

[FONT="]Blanks were cut to length. The dyed blank shows complete penetration through to the center of the blank.[/FONT]

[FONT="]Blanks were drilled on the lathe. Based on the drill cuttings, the stabilizing resin appeared to fully penetrate both the dyed and natural blanks. The dyed blank tended to drill a little warmer, and the ribbons tended to clump more than the natural blank. Constant's blanks drilled much smoother than the commercially stabilized blank, and much nicer then a non-stabilized blank. [/FONT]

[FONT="]Tubes were glued with fast dry Gorilla glue. Some blue dye bleeding was apparent with the dyed blank.[/FONT]

[FONT="]I still have to finish the pens, but wanted to get this review done and submitted sooner than later. I expect finish turning will go as smoothly as the rough turning for this review. If there is a change to these conclusions after finish turning, I will add to this post at that time.[/FONT]

[FONT="]Conclusions / recommendations:[/FONT]

[FONT="]The blanks were well dimensioned to accommodate most pen sizes, easy to cut, drill, turn, and sand. They were harder than non-stabilized maple, but not as hard as commercially stabilized blanks. The dye penetrated the blank completely, but with some streaking of colors and some natural grain lines. The stabilizing resin appeared to completely penetrate to the center of the blanks. The blanks finished as well as a commercially stabilized dyed blank, and took a better polish after sanding than a non-stabilized blank.[/FONT]

[FONT="]From a consumer's perspective, these stabilized and dyed blanks should be in a competitive market with other companies offering similar choices in wood figure and dye colors.[/FONT]

<<edited 11/15/09 to include link for finished pen>>

The finished pen can be seen here:

http://www.penturners.org/forum/showthread.php?t=54276

[FONT="]Pen Blanks provided by: Constant Laubscher of www.lazerlinez.com [/FONT]

[FONT="]I received these blanks at the end of August, and started working them on September 19, 2009. Both blanks were greater than 3/4-inches square, at least 5-1/2 inches in length, surfaced on four sides, and straight with no warping, bowing, or twisting. The blue dyed blank in square form showed signs of blue and purple hues on all four sides. The natural blank was cut from two tone material, and showed promising fiddleback/tiger stripe figure. [/FONT]

[FONT="]For comparison purposes for this review discussion, I also turned a non-stabilized, non-dyed birdseye maple blank and a commercially stabilized dyed box elder burl blank using the same techniques (no photos of these comparison blanks though) .[/FONT]

[FONT="]All blanks were turned between centers using a spindle roughing gouge with little to no signs of tearout. After the blanks were fully round, the non-stabilized maple blank cut nice curls, whereas the stabilized blanks all cut short chips. The commercially stabilized blank appeared to be the hardest when turning, and Constant's stabilized blanks cut somewhere between the non-stabilized blank and commercially stabilized blank. [/FONT]

[FONT="]All blanks were dry sanded through 400-grit using Klingspor's gold paper, then dry sanded through 2000-grit using the grey automotive wet/dry paper. When sanding through 400-grit, more resin accumulated on Constant's blanks in comparison to the commercially stabilized blank, and more so with Constant's dyed blank compared to his natural blank. When sanding through the 600- to 2000-grit range, Constant's dyed blank left more color dust on the sandpaper, in comparison to the commercially stabilized blank which left a near-white dust. After sanding, Constant's blanks appeared to be similar to the commercially stabilized blank in shine, and were considerably better than the non-stabilized blank. [/FONT]

[FONT="]All blanks were polished with EEE and Shellawax. Constant's blanks polished as well as the commercially stabilized blank; although, the non-stabilized blank appeared to polish equally as well at this point. The blue/purple hues in Constant's dyed blank remained throughout this rough turning and polishing, with some grain lines that did not take the dye. A picture of Constant's rough-turned, sanded, and polished blanks are shown below:[/FONT]

[FONT="]Blanks were cut to length. The dyed blank shows complete penetration through to the center of the blank.[/FONT]

[FONT="]Blanks were drilled on the lathe. Based on the drill cuttings, the stabilizing resin appeared to fully penetrate both the dyed and natural blanks. The dyed blank tended to drill a little warmer, and the ribbons tended to clump more than the natural blank. Constant's blanks drilled much smoother than the commercially stabilized blank, and much nicer then a non-stabilized blank. [/FONT]

[FONT="]Tubes were glued with fast dry Gorilla glue. Some blue dye bleeding was apparent with the dyed blank.[/FONT]

[FONT="]I still have to finish the pens, but wanted to get this review done and submitted sooner than later. I expect finish turning will go as smoothly as the rough turning for this review. If there is a change to these conclusions after finish turning, I will add to this post at that time.[/FONT]

[FONT="]Conclusions / recommendations:[/FONT]

[FONT="]The blanks were well dimensioned to accommodate most pen sizes, easy to cut, drill, turn, and sand. They were harder than non-stabilized maple, but not as hard as commercially stabilized blanks. The dye penetrated the blank completely, but with some streaking of colors and some natural grain lines. The stabilizing resin appeared to completely penetrate to the center of the blanks. The blanks finished as well as a commercially stabilized dyed blank, and took a better polish after sanding than a non-stabilized blank.[/FONT]

[FONT="]From a consumer's perspective, these stabilized and dyed blanks should be in a competitive market with other companies offering similar choices in wood figure and dye colors.[/FONT]

<<edited 11/15/09 to include link for finished pen>>

The finished pen can be seen here:

http://www.penturners.org/forum/showthread.php?t=54276

Last edited: