You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

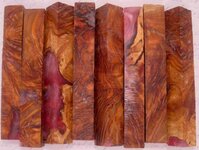

Some newest castings

- Thread starter mywoodshopca

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

toddlajoie

Member

Very nice, I like the harmony of the acrylic tones with the wood. I think I like that better than the drastic contrast styles (bright blue wit warm burl colors...) but both have their appeal, and to each his own, but yours are simply excerllent.

bitshird

Member

Jason, those are some beautiful blanks, did you use Polyester or Alumilite?

mywoodshopca

Member

Thanks Guys.

Ken I used Crystal Clear Alumilite and pearlex with these.

I split the alumilite into 2 cups, one was mixed with red dye then red pearlex added, the other was left clear and white pearlex was added, both were poured at the same time into the molds.. They blended together but enough to leave a nice look

Ken I used Crystal Clear Alumilite and pearlex with these.

I split the alumilite into 2 cups, one was mixed with red dye then red pearlex added, the other was left clear and white pearlex was added, both were poured at the same time into the molds.. They blended together but enough to leave a nice look

Can you clarify something for me please?

Hi Jason,

Can you clarify something for me please?

When you say 2 cups, do you mean the following?

How much time (in minutes) do you have after mixing both cups before pouring?

Did I miss anything?

TIA.

Hi Jason,

Can you clarify something for me please?

I split the alumilite into 2 cups, one was mixed with red dye then red pearlex added, the other was left clear and white pearlex was added, both were poured at the same time into the molds.. They blended together but enough to leave a nice look

When you say 2 cups, do you mean the following?

- Cup #1 --> part A & B (Alumilte Water Clear) with red dye/red pearlex, mixed ready to pour.

- Cup #2 --> part A & B (Alumilte Water Clear) with white pearlex, mixed reday to pour

- Pour the cups at the same time

How much time (in minutes) do you have after mixing both cups before pouring?

Did I miss anything?

TIA.

mywoodshopca

Member

Hi Jason,

Can you clarify something for me please?

When you say 2 cups, do you mean the following?Did I interpret it correctly?

- Cup #1 --> part A & B (Alumilte Water Clear) with red dye/red pearlex, mixed ready to pour.

- Cup #2 --> part A & B (Alumilte Water Clear) with white pearlex, mixed reday to pour

- Pour the cups at the same time

How much time (in minutes) do you have after mixing both cups before pouring?

Did I miss anything?

TIA.

Hi Branden,

What I did was add partA, mix in the dye and the pearlex, then when I had them all mixed up well, I added the Part B.

BUT now for future ones..

Add dye to both. I was not impressed the way it was almost too see through. And some of the smaller voids inside the blank didnt turn out well with the white alumilite, it almost looked like a slurry sanded into the cracks..

So my next step will be:

Measure off PARTA, add dye and pearlex

Measure off PARTB, add dye and pearlex

Once colors are what you want and your happy (dont mix part B until then so you buy youself some time to mix things up right)

Add Part B to each one and mix about 30-60 seconds.

Pour both cups into the molds and they will blend together pretty well (almost too well) another way around this is to wait about a minute between pours, but you are getting close on time then depending how fast your alumilite sets.

Working with resin, you could do the same thing but time the second pour to whatever time you need to allow the first pour to start getting ready to set.

Hope this helps

Jason

MesquiteMan

Retired Head Moderator

Why not mix your entire amount that you need of both parts with no color or pearlex. Then split the mixed resin into 2 cups and add what colorant you want to each and pour. This way you have plenty of time to get the 2 parts mixed. Mixing in the dye and powder is the easy part. Just a suggestion.

mywoodshopca

Member

Why not mix your entire amount that you need of both parts with no color or pearlex. Then split the mixed resin into 2 cups and add what colorant you want to each and pour. This way you have plenty of time to get the 2 parts mixed. Mixing in the dye and powder is the easy part. Just a suggestion.

I was afraid I would run out of time as I wanted to play with the colors to get them right. I know I have about 5-6 minutes, but thought it would be easier to have them premixed in the smaller cups then to mix and pour into the smaller cups.. saved dirtying another dish I guess lol

MesquiteMan

Retired Head Moderator

You will have more time with the method I suggested. If you mix one cup as you are doing now, the time starts once it is mixed up. Then you have to mix the other cup while the first one sits there cooking. A you know, the most critical part is getting the 2 components mixed thoroughly. Adding the dye is the easy part. If you mix it all at one time, then add the dye, they are both cooking at the same rate and it takes less time to mix in the dye than it does to mix the 2 components.

All that said, I have yet to have a batch of crystal clear or even water clear set up on me before I got it in the pot. You have much more time than you realize!

All that said, I have yet to have a batch of crystal clear or even water clear set up on me before I got it in the pot. You have much more time than you realize!

mywoodshopca

Member

You will have more time with the method I suggested. If you mix one cup as you are doing now, the time starts once it is mixed up. Then you have to mix the other cup while the first one sits there cooking. A you know, the most critical part is getting the 2 components mixed thoroughly. Adding the dye is the easy part. If you mix it all at one time, then add the dye, they are both cooking at the same rate and it takes less time to mix in the dye than it does to mix the 2 components.

All that said, I have yet to have a batch of crystal clear or even water clear set up on me before I got it in the pot. You have much more time than you realize!

Thanks

What pressure do you cast at? I mixed up a batch of the shipwreck wood the other day (a slab) and it turned out horrible. Air pockets and spongy areas (must have been some moisture still in the wood, but I heated it at 150 for about 10 minutes before hand.

MesquiteMan

Retired Head Moderator

I cast at 75 psi but I have 2 Binks pressure pots certified to at least 80 psi. Also, I heat my wood at 150 for a few HOURS before casting, 10 mkinutes is not long enough unless you know the wood is completely dry. Were the spongy areas actually resin of wood that was spongy? If wood, remember, Alumilite is NOT a stabilizing resin and has limited ability to penetrate the actual wood.

mywoodshopca

Member

It was spongy areas in the alumilite.. I am guessing airpockets that somehow trapped moisture.

My tank is rated for 50#.. so i cast at 42-45# max

My tank is rated for 50#.. so i cast at 42-45# max

MesquiteMan

Retired Head Moderator

If the Alumilite was spongy then it DEFINATELY was a moisture problem. Try cooking htem longer next time. I have left stuff in the oven for 8 hours when I thought they still had moisture in them. I also crack the door open just a little to allow the moisture to escape.

mywoodshopca

Member

If the Alumilite was spongy then it DEFINATELY was a moisture problem. Try cooking htem longer next time. I have left stuff in the oven for 8 hours when I thought they still had moisture in them. I also crack the door open just a little to allow the moisture to escape.

Yep, must have still been some moisture in it..

Good to know

Thanks Jason

jason_r

Member

Hi Branden,

I was not impressed the way it was almost too see through. And some of the smaller voids inside the blank didnt turn out well with the white alumilite, it almost looked like a slurry sanded into the cracks..

Jason

This is why the Resin Color Library has estimates on opacity.

It could always use more.