As promised....photo's!

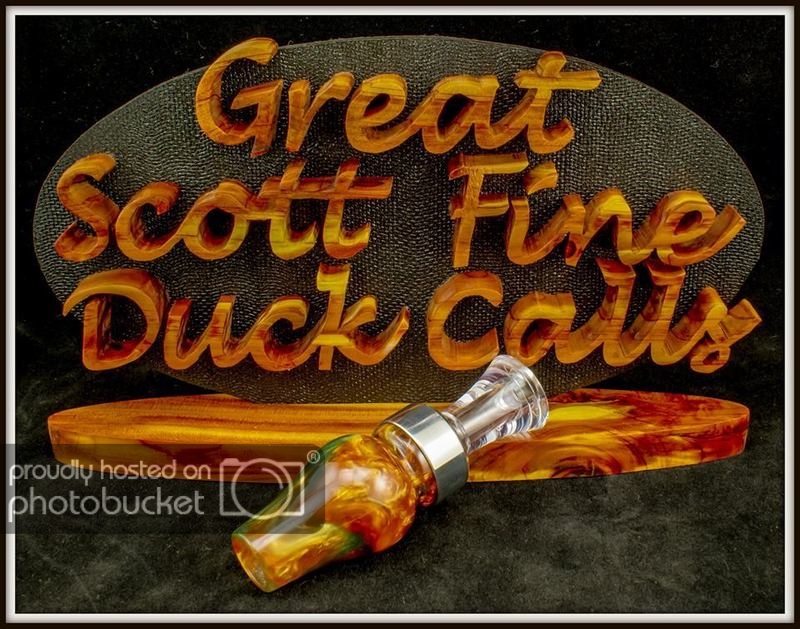

Took longer then expected to get everything sorted after such a long time away. Fun part was finding everything I needed to use! Lawn was as dry as I could hope for, so I ran the electrical and fired up the upright bandsaw. Started with Eastern Red Cedar, as I haven't had any in stock for quite sometime....even made some blanks out of ERC for duck calls(my stash).

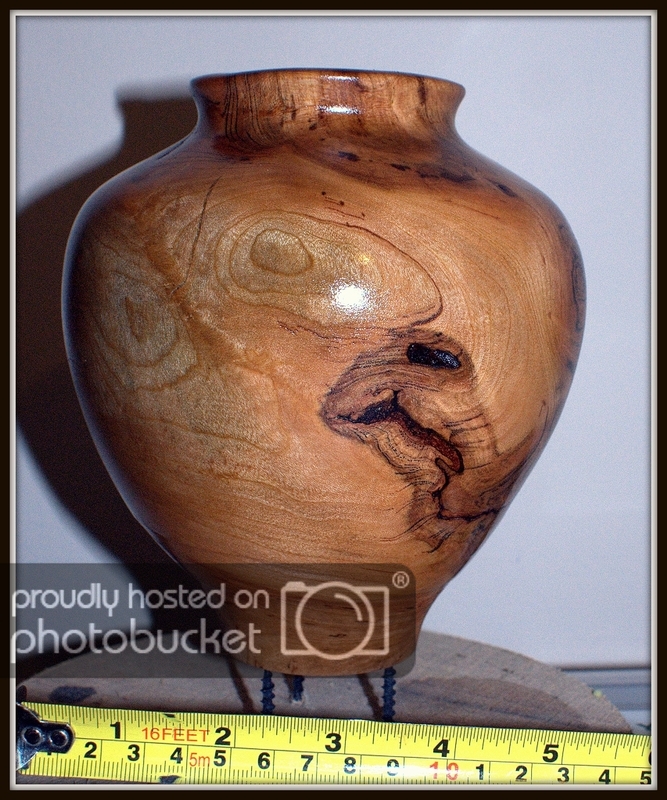

Since I was so excited, I just jumped right into some Southern Red Oak, even did some burl pieces! Little hard to see in the photo, but those premuim burls are awesome...with the limited number of them, those might have to be hidden away too. On the plus side, you've probably heard about the mythical 'Tiger Oak'(basically a 15* to the grain cut) that sell for outrageous prices? I cut these in the same manner.

Mill time!!! WOOHOO!!!

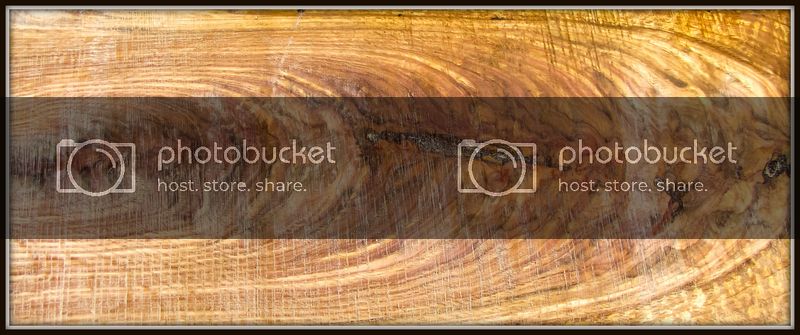

After going full on combat with the red wasps that took up homage under the tarp(yes, I fight dirty....and I won). I got the piece of Flame Boxelder set in place and ready. I was wrong earlier, the mill fired up on the first pull of the cord....

Sure made for some nice flitches! Not much 'flame', but generally finding any flame at all here in central Arkansa is like finding a unicorn. I cut a few, nine flitches, and left the remaining 'chunk' as a big piece for cutting bowl blanks out of when I get ready for them.

I'll get started earlier tomorrow, and cut some more! Thanks for taking time to see my enjoyment....

Scott (it was freakin' HOT) B