Phillip Kelley

Member

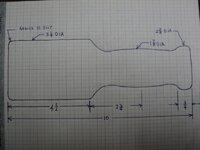

I recently saw a post from a new turner wanting to turn what my dad would simply call a beater. lol I had been gonna make myself one but just had never got around to it! A fellow coffee drinker at the old geezer coffee drinking club, recently gave me a rough piece of ash so I decided that was close enough to the round tuit. It looks a little cumbersome but it fits my hand and has a nice heft to it. I applied a light coat of BLO and

am waiting on the opportunity to beat on something with it.

am waiting on the opportunity to beat on something with it.