Woodchopper

Member

I'll try it again in the proper forum. I think. <g>

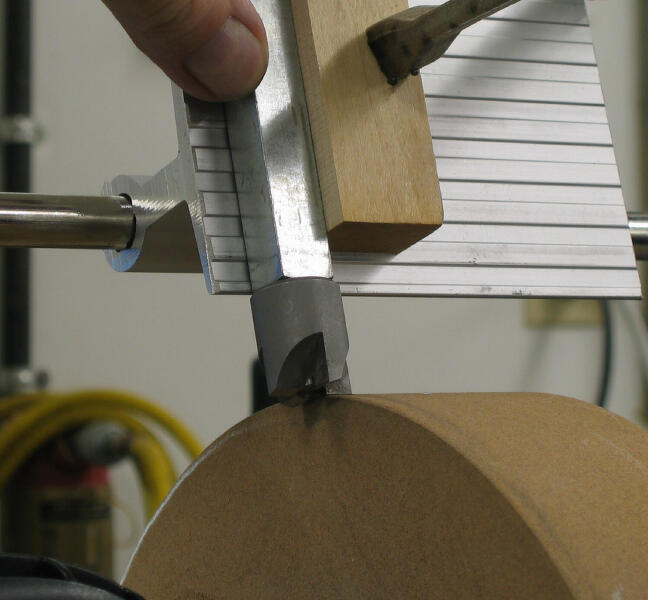

I made this jig to sharpen my pen mill and it worked pretty good. I used a Jet wet sharpener, but any grinder with an adjustable tool rest should work. I turned a half inch piece of square keystock to .250 inch on one end. Aligned the pen mill to the flats, adjusted the tool rest to where it's square, and angle matched. Using a marker and rotating the wheel by hand gave me the angle it needed. You just have to be careful to not get into the side of the wheel with the cutter that is not being sharpened. One could probably turn down a square acrylic to do the same. A light touch is all that's needed. I hope this helps someone. You guys have helped me tremendously. Thanks.

Hope I did it right this time.

Dell

I made this jig to sharpen my pen mill and it worked pretty good. I used a Jet wet sharpener, but any grinder with an adjustable tool rest should work. I turned a half inch piece of square keystock to .250 inch on one end. Aligned the pen mill to the flats, adjusted the tool rest to where it's square, and angle matched. Using a marker and rotating the wheel by hand gave me the angle it needed. You just have to be careful to not get into the side of the wheel with the cutter that is not being sharpened. One could probably turn down a square acrylic to do the same. A light touch is all that's needed. I hope this helps someone. You guys have helped me tremendously. Thanks.

Hope I did it right this time.

Dell