great work keith. i would be interested in a few more details about how you cut the pen notches in both the bottom and top... you didn't happen to blog this one did you?

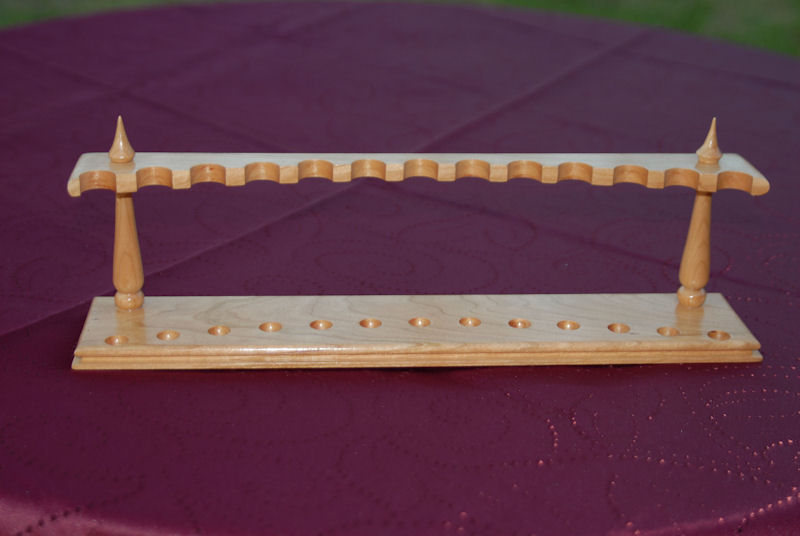

Andrew, I didn't blog this but I can describe it for you. I made a template out of 1/4 plywood and laid out the two curves. On the curve for the upper shelf I drilled a series of 3/4" holes using a fostner bit and on the curve for the lower shelf I drilled a series of 5/8" holes, again using a fostner bit. I then cut the template along the line of the upper shelf using my scroll saw.

I taped the upper template to a piece of 3" x 15" x 1/2" cherry, lining the straight edge of the template with the back of the shelf, and using the semi circular holes as a guide drilled 3/4" holes.

I taped the lower template to another piece of 3" x 15" x 1/2" cherry, lining the straight edge of the template with the front of the shelf. I then mounted a 1/2" core box bit in my plunge router, along with a

router template guide . The outside diameter of the guide is 5/8" so it fit snugly in the holes I had drilled. I set the plunge depth and routed out all the holes in the lower shelf.

I then taped the upper and lower shelves together, marked where the columns would be and drilled all the way through the upper shelf and halfway through the lower shelf with a 3/8" bit.

Then I routed the profiles on the upper and lower shelf edges using my table router. Then I cut the arc on the upper shelf on my scroll saw.

The last thing to do was to turn the matching columns and finials.

Hope that helps.