alamocdc

Member

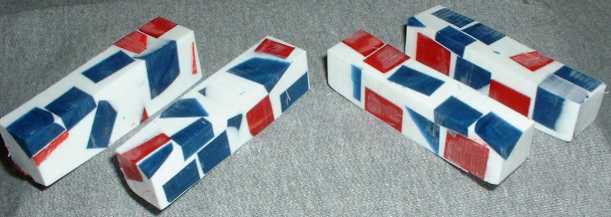

I made this up a few days ago and have been waiting for it to cure enough to cut. Using my "alternative" coloring method it seems to take two days instead of one, but I'm patient (sometimes). [} ] I have noticed that the translucent pearls and metal flakes "harden" better than the solids. The solids seem to be somewhat pliable, so I don't know how it will turn, but I'll find out tonight. This is Chrystal White with pieces of the Blue Pearl I did last week and my failed Bloodred particle bowling ball. The ball turns well, it just won't straighten. Anyway, here is what I came up with.

] I have noticed that the translucent pearls and metal flakes "harden" better than the solids. The solids seem to be somewhat pliable, so I don't know how it will turn, but I'll find out tonight. This is Chrystal White with pieces of the Blue Pearl I did last week and my failed Bloodred particle bowling ball. The ball turns well, it just won't straighten. Anyway, here is what I came up with.