adirondak5

Member

Hi all , my lathe got here this afternoon , after a long search I went with a Rikon 70 - 220 VSR . Woodcraft has a decent sale on them right now so I jumped on it . I also had a few questions I emailed Rikon customer support about regarding reversible chucks and compatability and my emails (multiple) were answered within 30 minutes which left a good impression.

I was a little worried as I've read all the horror stories of shipping damage with big brown and when it finally arrived this afternoon and I looked at the box I was even more worried . Although it was still a reasonable rectangular shape the box had seen better days , it had tears and just looked beat .

After opening the box I felt better , the lathe itself is incased inside form fitting Styrofoam and the was what appears to be 1/8 plywood at both ends of box . So far all looks good , everything is in the box , paperwork , wrenches , centers , knockout bar , face plate , tool holder , banjo , tool rest , tail stock , and lathe

I was impressed with the size of the lathe itself and worried about carrying it down the basement entry , I removed the tail-stock and the banjo and it was manageable , got it down on the workbench , where I also realized that I am going to have to build a stand for it , its a tad to high sitting on the workbench . I then cleaned the grease off everything and gave it a good look over .

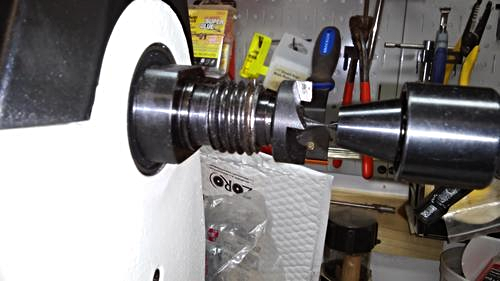

The ways are machined very nicely , the tail stock and the banjo slide along it nicely , the finish is nicely done . Its got some weight to it , the cam locks on the banjo and tail stock operate nicely , the centers line up pretty good right outta the box .

Plugged it in and hit the start button with the belt in the mid position (550 - 1650 rpm) at the low end I got 560 on the digital readout , high end 1800

It was quiet and smooth through the speed changes .

First impressions , seems like a very well built machine , I am pleased with what I see to this point . More to come when I figure out the stand for this lathe

I was a little worried as I've read all the horror stories of shipping damage with big brown and when it finally arrived this afternoon and I looked at the box I was even more worried . Although it was still a reasonable rectangular shape the box had seen better days , it had tears and just looked beat .

After opening the box I felt better , the lathe itself is incased inside form fitting Styrofoam and the was what appears to be 1/8 plywood at both ends of box . So far all looks good , everything is in the box , paperwork , wrenches , centers , knockout bar , face plate , tool holder , banjo , tool rest , tail stock , and lathe

I was impressed with the size of the lathe itself and worried about carrying it down the basement entry , I removed the tail-stock and the banjo and it was manageable , got it down on the workbench , where I also realized that I am going to have to build a stand for it , its a tad to high sitting on the workbench . I then cleaned the grease off everything and gave it a good look over .

The ways are machined very nicely , the tail stock and the banjo slide along it nicely , the finish is nicely done . Its got some weight to it , the cam locks on the banjo and tail stock operate nicely , the centers line up pretty good right outta the box .

Plugged it in and hit the start button with the belt in the mid position (550 - 1650 rpm) at the low end I got 560 on the digital readout , high end 1800

It was quiet and smooth through the speed changes .

First impressions , seems like a very well built machine , I am pleased with what I see to this point . More to come when I figure out the stand for this lathe