MikePittman

Member

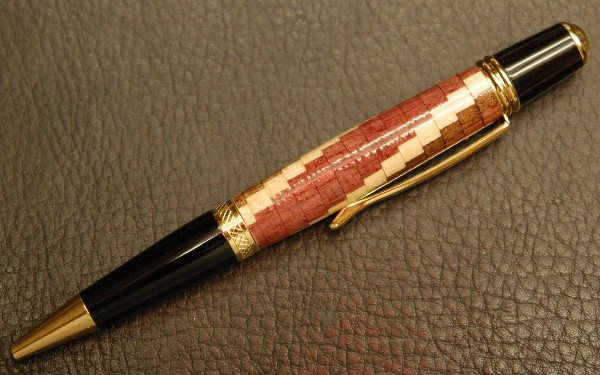

My first attempt at finishing a pen using CA glue. It came out ok but I was disappointed because it left a tiny ripple effect across the finish. I am not sure what I did wrong because I did 3 coats with 200, 600, and 2000 grit sandpaper in progression. I did watch the video on this site but I am at a loss what cause the small ripples. Any advise from anyone would be greatly appreciated.