Joey-Nieves

Member

1- The thickness between an inner thread and an outer thread, when you have a tapped hole inside a threaded tenon for the cap, can vary with the material your using to make the parts. Metal can be thinner, plastics have to be thicker or they can break, you may have to experiment with different materials.

3- the .7,.5,.8,1 are the pitch count or in metric the distance between the tips of the threads. THere are many different reasons to use a different pitch on a part. One consideration is that the bottom tip of the outside thread may be cut to close to the outer tip of an inside thread. A look at the cross section may show a weak area where the 2 cut threads get really close to each other. In that case a smaller pitch will help to keep the parts from breaking. This becomes critical in smaller diameter pens. Also since a .5 pitch is very fine it can easily be cross threaded if your drilled hole diameter is slightly to large. A 1mm pitch is coarser but may cause stress and rough threads from having to cut deeper into your material/part. My personal favorite is the .75 or .8 for threads.

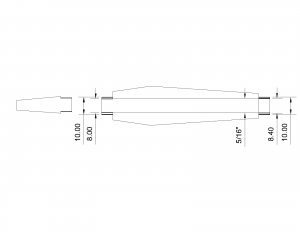

4- yes it can be done I do it frequently. However I have found that if your threaded hole for the refill/convertor is directly inside the cap threads that the hole needs to be threaded with an 8.4 or 8.5 tap, the convertors require a large hole to fit through than the ink cartridges. I use an 8mm or 5/16 or O drill bit and thread it with the 8.4 x.75 that Heritance Nibs use to sell. the 8,5 x 1 will work I just dont like that rough of thread and the bottom of the threads are not formed during tapping because of the size of the hole for the convertor. They still hold just fine.

Ok, so the pitch that you have found to work best is .75, would you say that 1mm wall thickness would work the less bridle materials?

As for the 10mm pen is this what your talking about:

Because this is what I want to Make.