Gary Max

Member

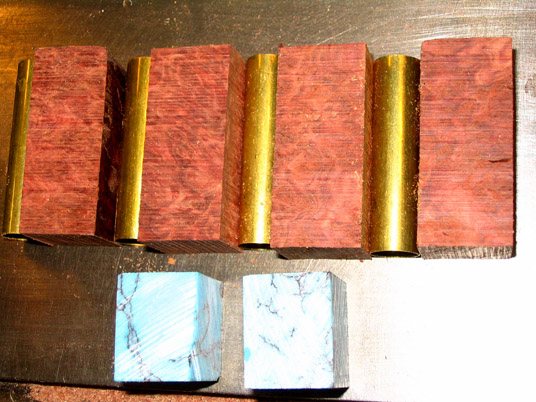

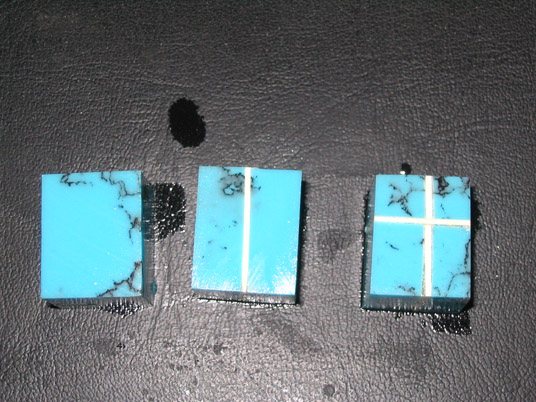

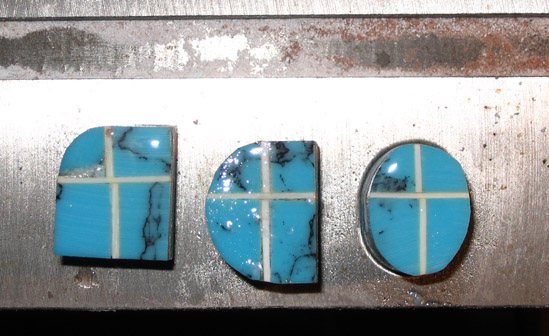

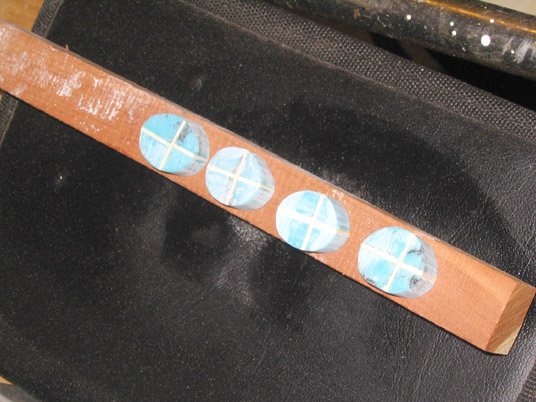

This is how I make a cross inlay---may not be the best or fastest but it works for me--I tried to take the enough pics to get you started.

Originally posted by GBusardo

<br />Thanks Gary, Someday I will try it, not sure I have the patience for it, but I hae a few friends that would love to get one at Christmas time.

Originally posted by GaryMGg

<br />FWIW, I've sold several of the cross inlay pens using blanks made by Eagle.

They ALL brought a return on investment that far exceeded many other pens I've sold.

I'm neither bragging nor trying to do anything to promote the blank maker but a fact is a fact. Y'all can also be sure that EVERYONE who buys a cross inlay blank from Ron Mc will also make a handsome return if they're selling theirs.

When I make time to make my own cross inlay blanks, I'll post the results on IAP.

Gary

Originally posted by Rifleman1776

<br />... the time and effort involved are very unlikely to translate into selling prices high enough to justify that time and effort.../quote]

This thread has conjured up two thoughts in my little mind...

1. Perhaps, since these are "hand crafted" pens, one might not expect to see machine precision down to .0005". To me, seeing a cross inlay that is just a hair off because it was done by hand is just as appealing to one that is perfectly mated by a machine.

2. As for the quote above, does it always have to be about the money? More often than not when someone comes up with a nice idea like this, someone inevitably brings up the fact that it is too time consuming or just not worth the effort. I totally disagree and think there are a lot more artists than assemblers hanging around here who take pride in their work regardless of the bottom line!

Could you imagine how dull the pen making world would be if everyone was concerned with the bottom line? We’d be awash in a sea of butt ugly, bushing to bushing slim lines made from yellow pine 2x4’s….with one coat of friction polish! And who would want to visit the "Show off your pen" forum then?

Gary, Thank you for taking the time to explain your process, I for one, am impressed. This is just one more idea to put in my "to try someday" file.

George

Originally posted by Texatdurango

Gary, Thank you for taking the time to explain your process, I for one, am impressed. This is just one more idea to put in my "to try someday" file.

George

Originally posted by bonsaibill

<br />It also works pretty well to make the cross on an oversized slab and then use a plug cutter to cut down into the slab with the cross centered in the plug. Then use a bandsaw to free the plug. Now you have a perfect circle with a cross in it. Now take the blank and use a forstner bit of the same size to make a hole that the plug fits perfectly. This works well, if you want a circlular insert and not an oval one.

Originally posted by Texatdurango

<br />Originally posted by Rifleman1776

<br />... the time and effort involved are very unlikely to translate into selling prices high enough to justify that time and effort.../quote]

This thread has conjured up two thoughts in my little mind...

1. Perhaps, since these are "hand crafted" pens, one might not expect to see machine precision down to .0005". To me, seeing a cross inlay that is just a hair off because it was done by hand is just as appealing to one that is perfectly mated by a machine.

2. As for the quote above, does it always have to be about the money? More often than not when someone comes up with a nice idea like this, someone inevitably brings up the fact that it is too time consuming or just not worth the effort. I totally disagree and think there are a lot more artists than assemblers hanging around here who take pride in their work regardless of the bottom line!

Could you imagine how dull the pen making world would be if everyone was concerned with the bottom line? We’d be awash in a sea of butt ugly, bushing to bushing slim lines made from yellow pine 2x4’s….with one coat of friction polish! And who would want to visit the "Show off your pen" forum then?

Gary, Thank you for taking the time to explain your process, I for one, am impressed. This is just one more idea to put in my "to try someday" file.

George

Judging from the time of your post, it appears you were typing just as I was posting. Please note my post just before yours.