wizard

Member

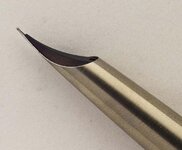

There may be a simple answer to this question and if so I apologize in advance for my lack of knowledge of machining. This is a pen in my collection made by Pilot Namiki called the MU/M90. I would like to know if anyone has any idea as to how this was made out of a solid block of stainless steel ? Can something like this even be possible on a metal lathe? Doc

Edit:

I know it's made from stainless steel and nib and pen are one piece:

Namiki :: Limited Editions - MU/M90 Fountain Pen

Edit:

I know it's made from stainless steel and nib and pen are one piece:

Namiki :: Limited Editions - MU/M90 Fountain Pen

Attachments

Last edited: