MesquiteMan

Retired Head Moderator

I had a need for a belt sander that was at least 12" wide. I could not use a typical widebelt sander since I needed to have the top of the belt unobstructed. I looked all over and could not find anything. I have a drum sander that basically uses a sandpaper belt for the conveyor and thought I could come up with something myself. While looking at the drum sander, it occured to me that it was very similar to a treadmill!

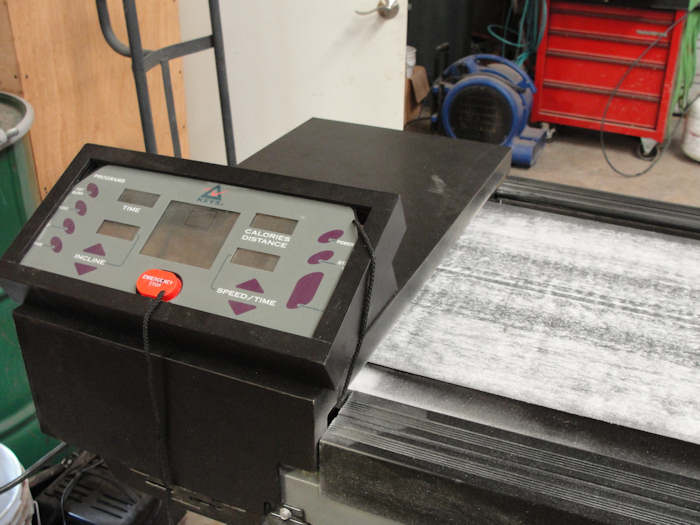

Of to Craig's List I went! I found a really nice treadmill for $50 and bought it. I then went online and found a company that will make any size sanding belt for you. I spent $40 for the belt, shipped. I removed all of the upright parts to the treadmill and disassembled the control board that is on the riser part that you hand on to for dear life! I took the plastic for the control board and cut it down on my saw and made a wood frame for it. I then welded up a steel frame with steel legs and fastened the treadmill to it. Lastly, I crafted a fence and made a new end cover to mount the control board on.

I now have a sander with capacity of 16" x 42" with variable speed from 52.8 feet per minute to 880 feet per minute. It works absolutely fantastic and I only have $90 in it if you don't count the cost of the steel frame and legs (I already had the steel). Here are some pictures as well as a link to a Youtube video.

Who ever knew sanding was such a good work out! After sanding for 20 minutes or so, according to the control board, I have burned a few hundred calories and ran a mile or more! I never even work up a sweat either! I should be in great shape after doing a lot more sanding!

[yt]MJppW06Kxjs[/yt]

Of to Craig's List I went! I found a really nice treadmill for $50 and bought it. I then went online and found a company that will make any size sanding belt for you. I spent $40 for the belt, shipped. I removed all of the upright parts to the treadmill and disassembled the control board that is on the riser part that you hand on to for dear life! I took the plastic for the control board and cut it down on my saw and made a wood frame for it. I then welded up a steel frame with steel legs and fastened the treadmill to it. Lastly, I crafted a fence and made a new end cover to mount the control board on.

I now have a sander with capacity of 16" x 42" with variable speed from 52.8 feet per minute to 880 feet per minute. It works absolutely fantastic and I only have $90 in it if you don't count the cost of the steel frame and legs (I already had the steel). Here are some pictures as well as a link to a Youtube video.

Who ever knew sanding was such a good work out! After sanding for 20 minutes or so, according to the control board, I have burned a few hundred calories and ran a mile or more! I never even work up a sweat either! I should be in great shape after doing a lot more sanding!

[yt]MJppW06Kxjs[/yt]

Attachments

Last edited: