You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Experiments with segments

- Thread starter vwa3guy

- Start date

Signed-In Members Don't See This Ad

See more from vwa3guy

Hello Rick

I really do not want to hijack the OP's thread here but since you asked, this was the pen made with those pieces shown. have done a couple of these and have show them a few times.

To make this pen and many others with some segmentation I use a router set up on my lathe. Did these a few years ago basically when we started the segmentation forum. Been away for a couple years due to health reasons but will return soon. Here is the thread I started back then called "My Jig"

www.penturners.org/forum/f179/my-jig-104253/

No problem Rick. You ever want to step your game up and I can be of some help, just give me a hollar. That goes for anyone else also. I am back in the game. Ready to play.

Signed-In Members Don't See This Ad

jttheclockman

Member

If you would allow me to make a suggestion. As good as they look now you will do yourself a bit of a favor by trying to do equal segmentation. You are trying to the same pattern, but the pieces should be of equal size too unless you are doing something random and from this photos this is not random. There is definetly a pattern. Also try to keep all the cuts square when you glue them up and drill straight through the pattern. Any slight angle will show in the pattern. Maybe the second pen is more random but the first is certainly a pattern.

You are well on your way though. Good luck.

You are well on your way though. Good luck.

Last edited:

vwa3guy

Member

thank you! this is why I am posting. any and all feedback!

I just made myself a sled for my table saw last weekend so my "slivers" as my girlfriend calls them are much more square than they used to be. I have found lately that my 7mm drill bit tends to wander, a LOT. I think it's time for a new one. I've been using the same 7mm bit for almost 2 years now.

is there a specific jig or something for cutting on the sled or for assembling peices?

I haven't even gotten to the point of measuring tubes and such yet. I'm just taking random slivers and just gluing it by hand.

I just made myself a sled for my table saw last weekend so my "slivers" as my girlfriend calls them are much more square than they used to be. I have found lately that my 7mm drill bit tends to wander, a LOT. I think it's time for a new one. I've been using the same 7mm bit for almost 2 years now.

is there a specific jig or something for cutting on the sled or for assembling peices?

I haven't even gotten to the point of measuring tubes and such yet. I'm just taking random slivers and just gluing it by hand.

jttheclockman

Member

Hello Ryan

When doing segmenting you will find there are many ways to accomplish what you want to do. You need to find a way that works for you.

It the type of segmenting you are currently doing it is a simple design and is called stacking. There are 2 ways to make those type blanks. Cut all the pieces and glue together and drill for the tube afterwards. Or you can drill the individual pieces ahead of time and now stack them on the tube, gluing as you go. Doing it that way you will not get the bit to wander because the pieces are not very long. The longer the piece is and the more different woods you stack (the grain patterns are different with each spiecies of wood) the more the bit wants to wander.

There is no measuring of the tubes. Just take the woods you want to use and stack them in the order you want. Now lay the tube next to the stack and center the tube on the stack so that you have the same equal pieces on both sides of center of the tube. Simple. You now will probably have to cut off slivers from both ends of the stack. Just allow a little on each end for trueing the blank latter. Just keep the tube in the center of the stack.

Here is my jig I use for cutting slices. very simple jig that I use stop blocks to keep the size of the pieces equal. I use clamps to keep my hands away from the blade when working with small pieces. You can do the same type jig on a bandsaw too.

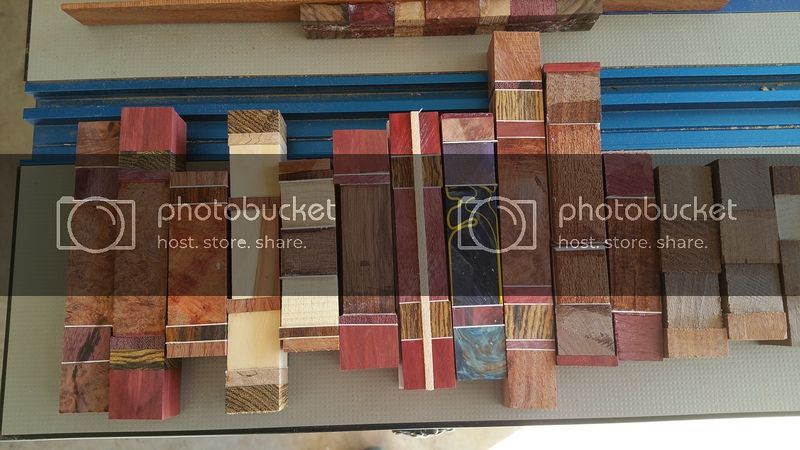

Also here is an example of stack cutting and assembling. I cut the pieces before I placed them on the tube. I then used epoxy glue and glued all piece and also glued the tube in together. Works well for that type segmenting.

When doing segmenting you will find there are many ways to accomplish what you want to do. You need to find a way that works for you.

It the type of segmenting you are currently doing it is a simple design and is called stacking. There are 2 ways to make those type blanks. Cut all the pieces and glue together and drill for the tube afterwards. Or you can drill the individual pieces ahead of time and now stack them on the tube, gluing as you go. Doing it that way you will not get the bit to wander because the pieces are not very long. The longer the piece is and the more different woods you stack (the grain patterns are different with each spiecies of wood) the more the bit wants to wander.

There is no measuring of the tubes. Just take the woods you want to use and stack them in the order you want. Now lay the tube next to the stack and center the tube on the stack so that you have the same equal pieces on both sides of center of the tube. Simple. You now will probably have to cut off slivers from both ends of the stack. Just allow a little on each end for trueing the blank latter. Just keep the tube in the center of the stack.

Here is my jig I use for cutting slices. very simple jig that I use stop blocks to keep the size of the pieces equal. I use clamps to keep my hands away from the blade when working with small pieces. You can do the same type jig on a bandsaw too.

Also here is an example of stack cutting and assembling. I cut the pieces before I placed them on the tube. I then used epoxy glue and glued all piece and also glued the tube in together. Works well for that type segmenting.

vwa3guy

Member

jttheclockman

Member

I do respect your enthusiasm that is for sure. But you are going to have problems with some of those. You do have to watch your grain direction as I said the bit will wander off. Hope you at least sand them flush and make a square out of them. Good luck. Good way to use up scraps though.

thewishman

Member

You have some really interesting and beautiful segments glued up. Nice work!

Jgrden

Member

Not too shabby there fellow. Nice.

jttheclockman

Member

John .... JT, I understand how to safely cut the pieces stacked end to end but how did you cut the thin strips in the dark and light piece pictured above? Some type of jig? Bandsaw? Tablesaw? any photos? Thanks.

Hello Rick

I really do not want to hijack the OP's thread here but since you asked, this was the pen made with those pieces shown. have done a couple of these and have show them a few times.

To make this pen and many others with some segmentation I use a router set up on my lathe. Did these a few years ago basically when we started the segmentation forum. Been away for a couple years due to health reasons but will return soon. Here is the thread I started back then called "My Jig"

www.penturners.org/forum/f179/my-jig-104253/

jttheclockman

Member

Thanks John. I haven't quite crossed that threshold YET. Working in that direction....

No problem Rick. You ever want to step your game up and I can be of some help, just give me a hollar. That goes for anyone else also. I am back in the game. Ready to play.

moke

Member

Awesome advice John.....two key words in segmenting are...

parallel and purpendicular....if you are having issues with that, who says you have to segment at 90 degrees.....how about 45? It is much more forgiving.

Also as John said some of those "latest" blanks may explode as you turn them....to avoid that, as I am sure you know square them up, take very light cuts and I might stop as I am turning them down and flood them with thin CA.

Just my .02

parallel and purpendicular....if you are having issues with that, who says you have to segment at 90 degrees.....how about 45? It is much more forgiving.

Also as John said some of those "latest" blanks may explode as you turn them....to avoid that, as I am sure you know square them up, take very light cuts and I might stop as I am turning them down and flood them with thin CA.

Just my .02