kmetzger

Member

I just completed the Crafts Supplies cigar holder and realize I should have cut at least one of the brass tubes shorter. The thing is a massive 9 inches long. https://www.woodturnerscatalog.com/...th-Cutter-Punch-Tip-Kit?term=cigar+holder+kit

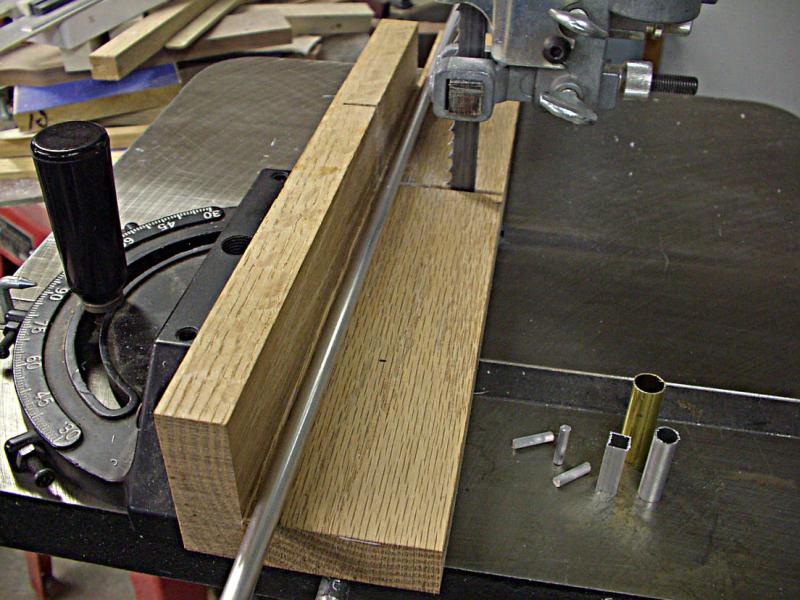

The instructions recommend cutting the tubes to length with a hacksaw, but I'm having a hard time visualizing how to hold the tube in a vise and cut a square edge if I decide to make another one. Any suggestions? And what would be the best overall length for a cigar holder if I wanted to sell one? Your ideas appreciated.

The instructions recommend cutting the tubes to length with a hacksaw, but I'm having a hard time visualizing how to hold the tube in a vise and cut a square edge if I decide to make another one. Any suggestions? And what would be the best overall length for a cigar holder if I wanted to sell one? Your ideas appreciated.