amtechrs

Member

Hello all,

I'm preparing to pour a sort of hybrid blank, using laser cut segments. Please excuse the photo dump, but just want to get my idea (hairbrained as it may be) across. I've only used Alumilite slow for my castings, with generally okay results. I really don't want any air bubbles in these. I do use a pressure pot. What I've done is to make a 'sacrificial' center box that supports some ornate segments, along with an outer sacrificial box to give space for the resin to flow around and through the oranate pieces. I'm wondering what you all might think would be best to use as far as the resin is concerned? I thought about deep pour or even table top epoxy, just to give more time and less viscosity to seep into all the crevices. I was hoping to mix two colors using mica powder, but not waiting for the resin to heat up and start curing before pouring. I'm obviously pretty new at this, so any pointers or suggestions are much appreciated! Again, sorry for the photo dump....

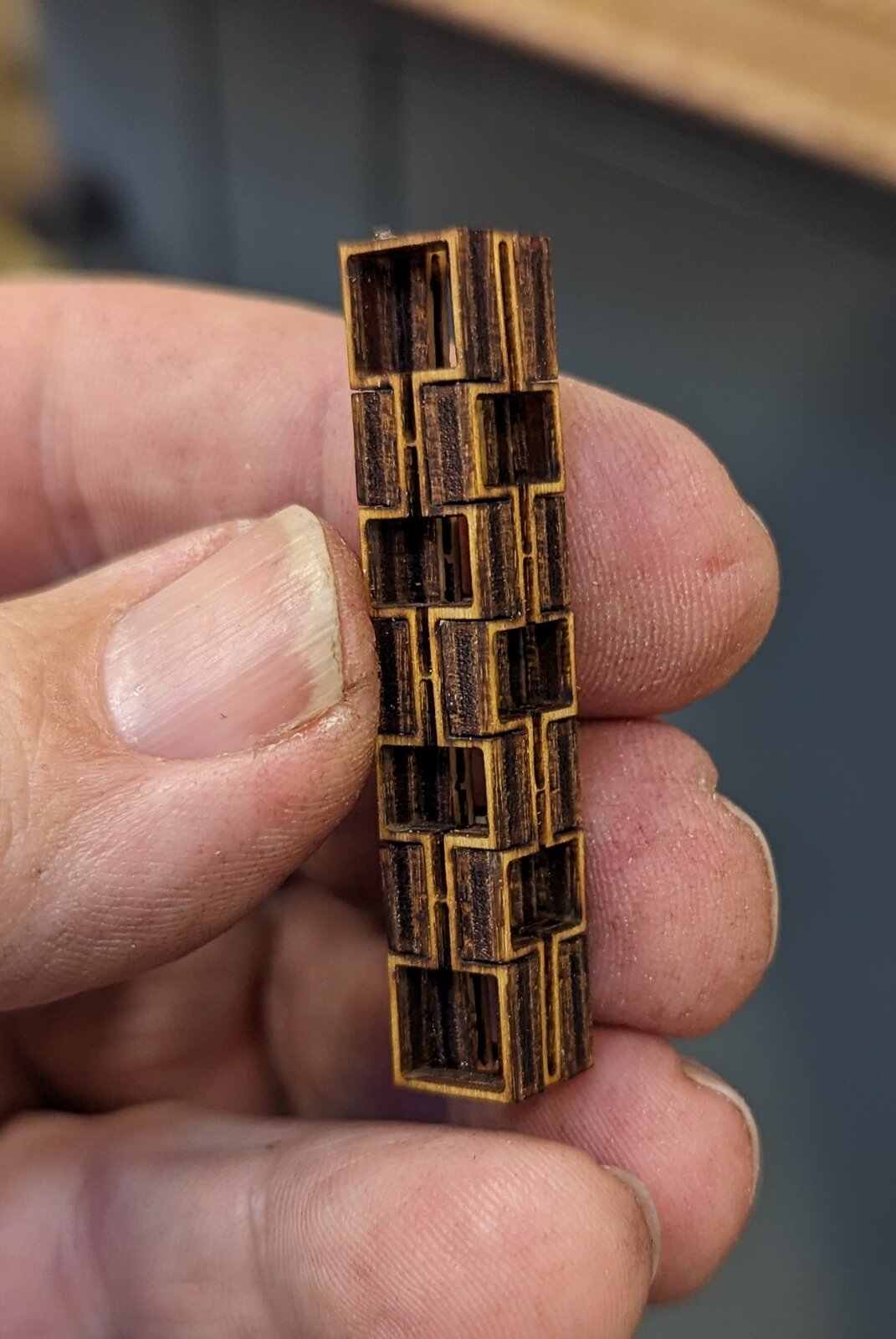

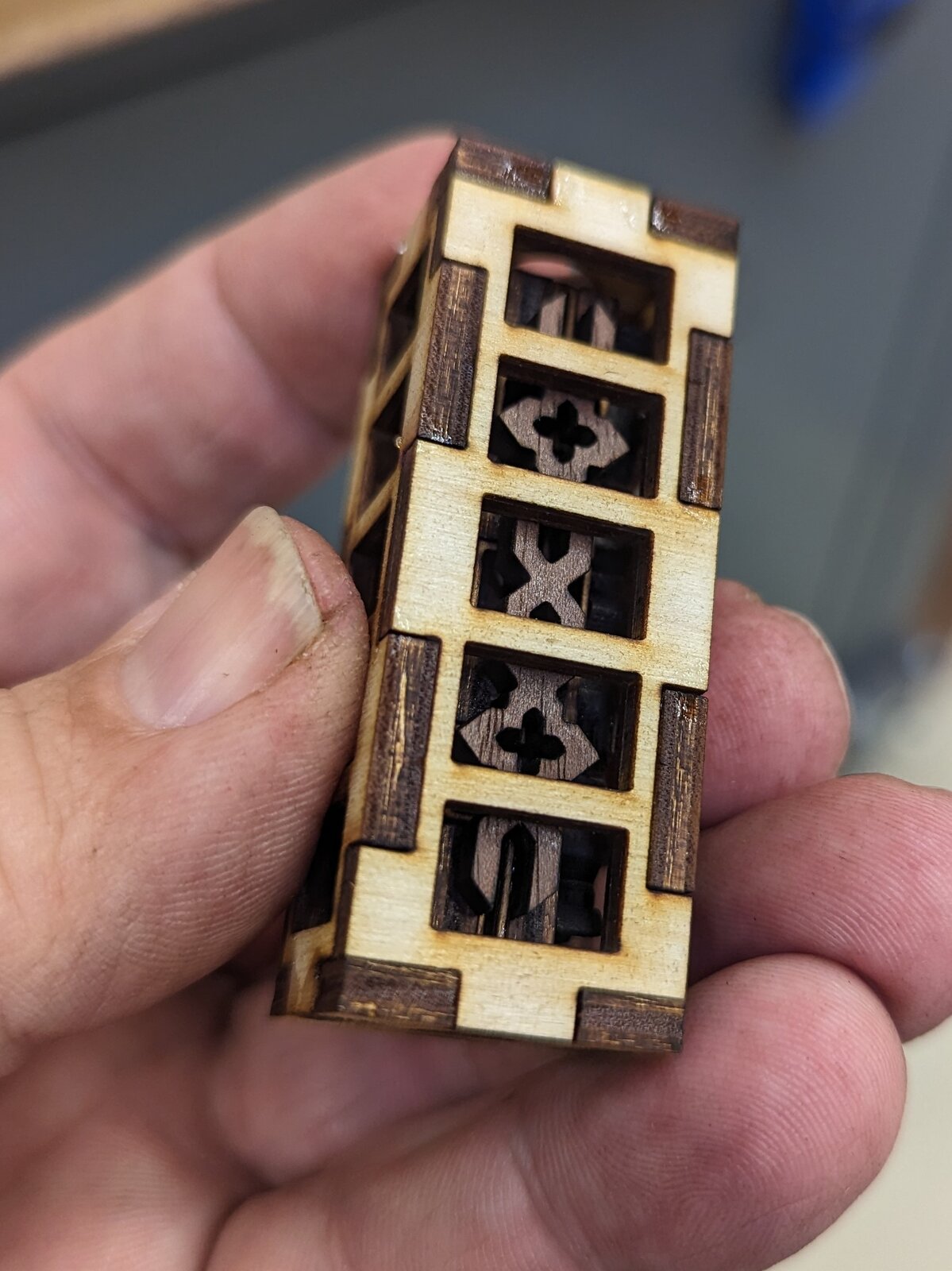

Here is the center (supporting) box, that the ornate pieces are spot glued to;

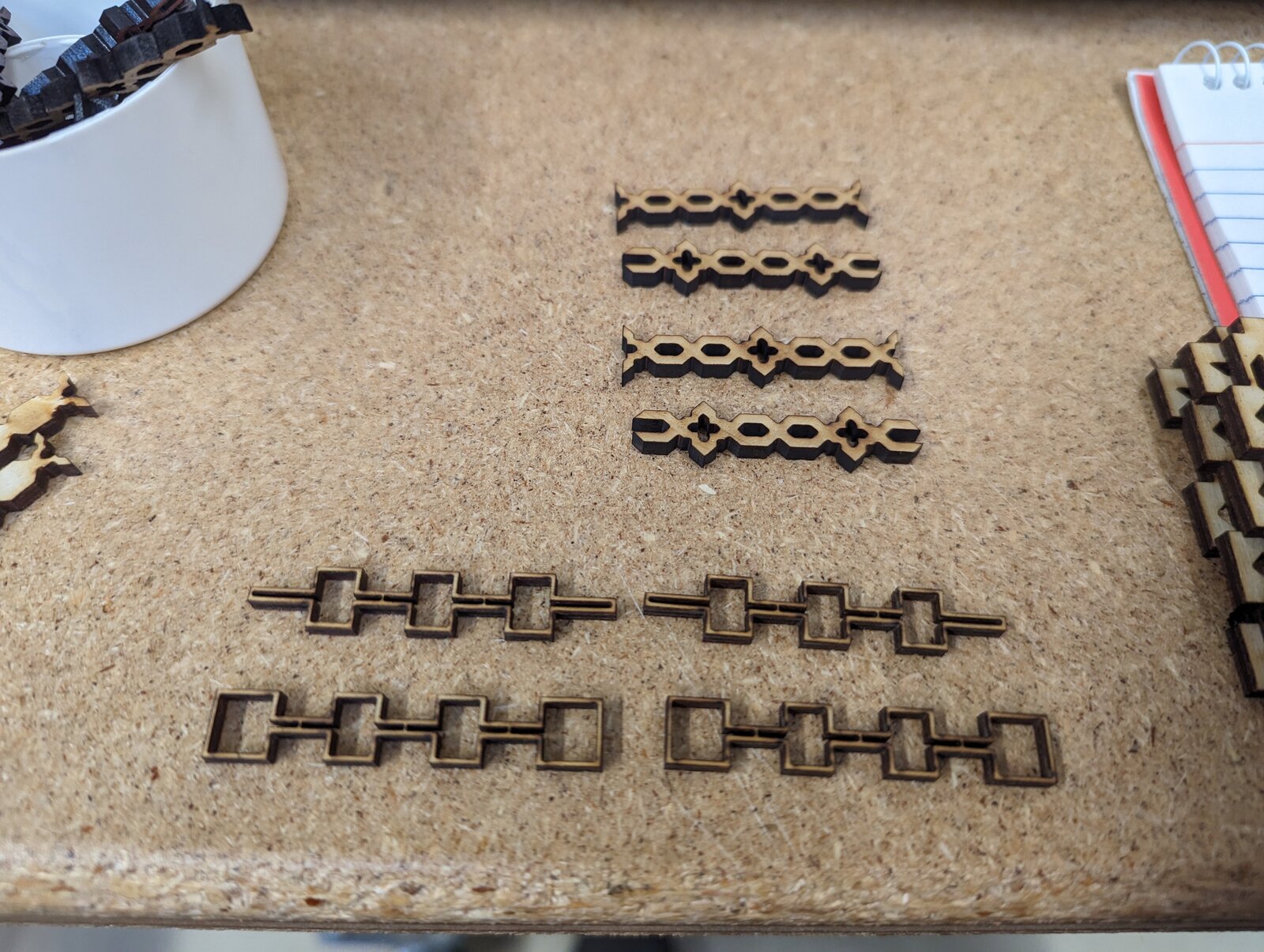

Before assembling;

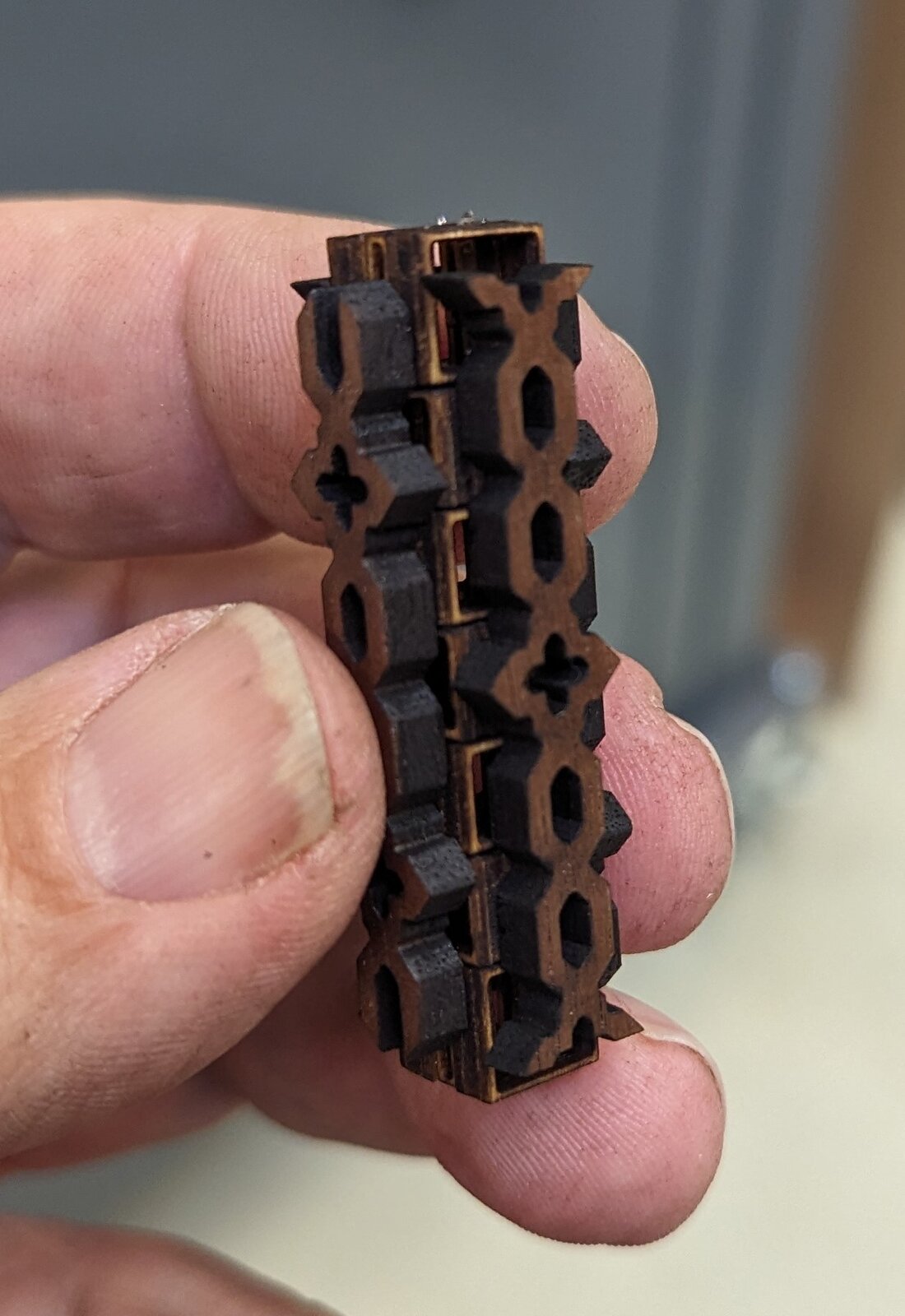

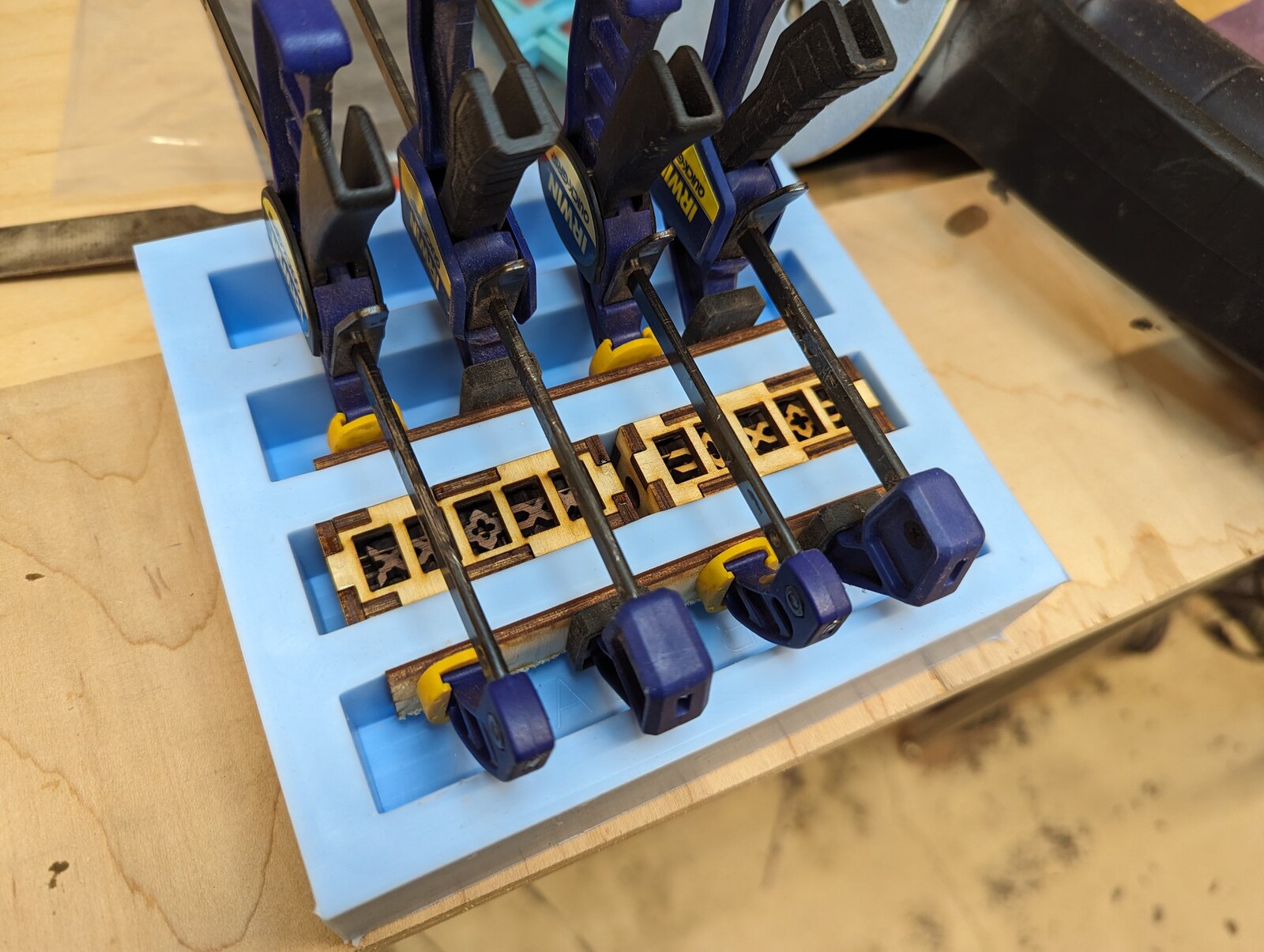

Using a temporary box to locate the ornate segments onto the inner box.

Inner box with ornate pieces glued to it

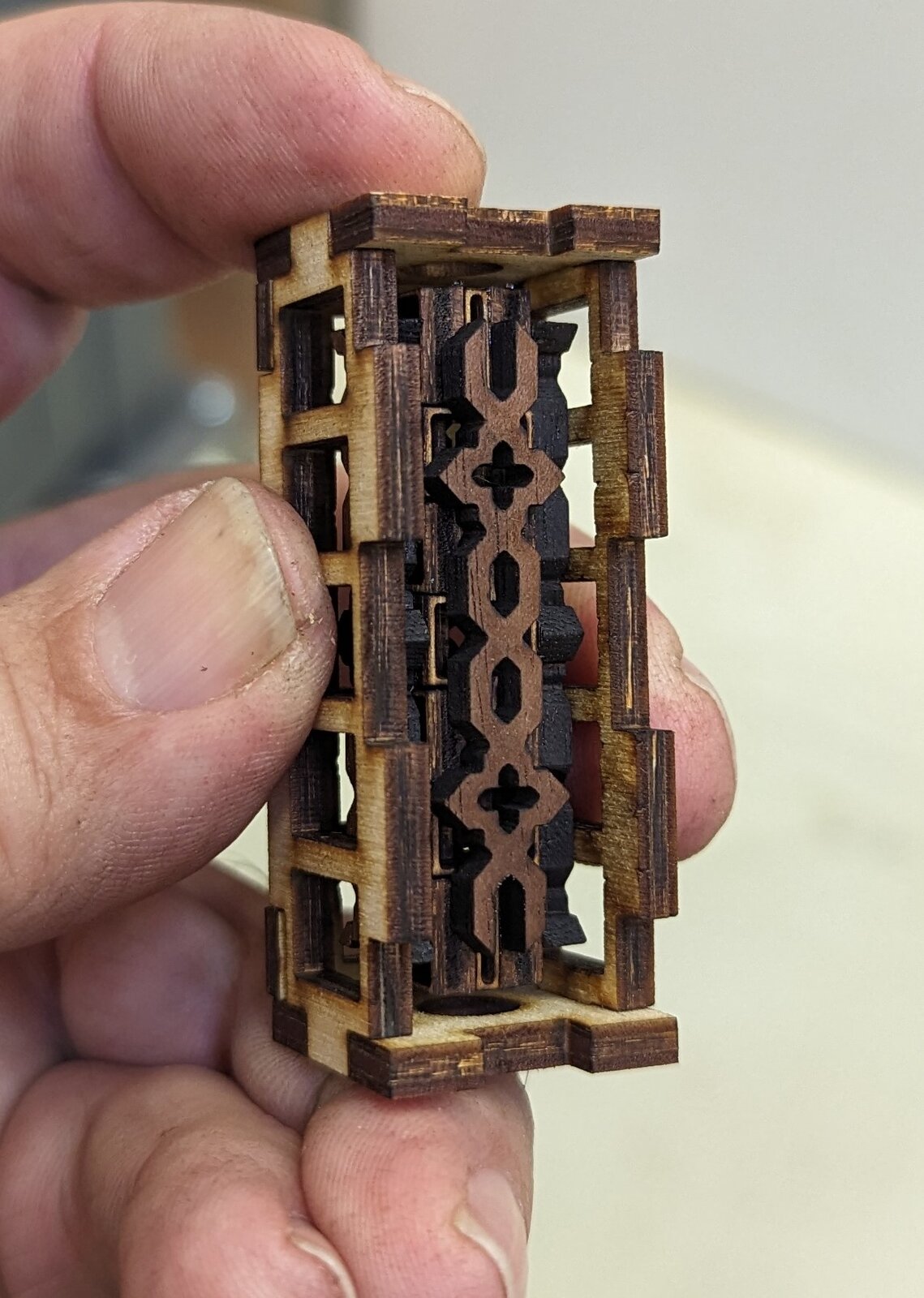

Outer sacrificial box assembled around the ornate section box.

And finaly assemblies in the blank mold;

Let me know if you just think I'm just plain crazy. I'm not expecting a great result, but really testing the waters for adapting this further...

Again, thank you for your consideration and any feedback!

Best,

Richard

I'm preparing to pour a sort of hybrid blank, using laser cut segments. Please excuse the photo dump, but just want to get my idea (hairbrained as it may be) across. I've only used Alumilite slow for my castings, with generally okay results. I really don't want any air bubbles in these. I do use a pressure pot. What I've done is to make a 'sacrificial' center box that supports some ornate segments, along with an outer sacrificial box to give space for the resin to flow around and through the oranate pieces. I'm wondering what you all might think would be best to use as far as the resin is concerned? I thought about deep pour or even table top epoxy, just to give more time and less viscosity to seep into all the crevices. I was hoping to mix two colors using mica powder, but not waiting for the resin to heat up and start curing before pouring. I'm obviously pretty new at this, so any pointers or suggestions are much appreciated! Again, sorry for the photo dump....

Here is the center (supporting) box, that the ornate pieces are spot glued to;

Before assembling;

Using a temporary box to locate the ornate segments onto the inner box.

Inner box with ornate pieces glued to it

Outer sacrificial box assembled around the ornate section box.

And finaly assemblies in the blank mold;

Let me know if you just think I'm just plain crazy. I'm not expecting a great result, but really testing the waters for adapting this further...

Again, thank you for your consideration and any feedback!

Best,

Richard