Rich L

Member

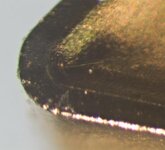

I just got through turning a bunch of rectangular 1.5 foot acrylic blanks into round blanks using a carbide insert tool. This is a rare occurrence! I estimated that the lathe went round about 230,000 times turning this roughly 5/8 stock. I thought, for fun, I'd take a picture of the insert to see if there was any appreciable wear and ask if others have found the same or similar result. This insert has been used before on some metal cutting - steel and brass so there is some initial wear. The insert type is TNMG221 with a 1/4" inscribed circle. The corner radius is 1/64". It boiled down to about 4.5 hours of constant turning and I see nothing significant to report from the acrylic.

If this is a yawner, I apologize. I think a lot of you use HSS tooling but mine are all either indexable or solid carbide. Do you find that your carbide lasts forever in this stuff? I would not expect much wear but just checking.

Cheers,

Rich

If this is a yawner, I apologize. I think a lot of you use HSS tooling but mine are all either indexable or solid carbide. Do you find that your carbide lasts forever in this stuff? I would not expect much wear but just checking.

Cheers,

Rich