This may be pedantic but here is my thinking

Lathe (as sdindc said)

- note the morse taper of the lathe (probably MT2 but you'll want to verify)

Toolrest (hopefully came with your lathe)

Tailstock center - also matching MT

Mandrel to match the MT - there are two general options

- The usual 'rod' mandrel or the turn between center (TBC) mandrel system

Blank prep

Pen kit you want to work (obviously)

A blank to work on

A method to cut the blank down to appropriate length

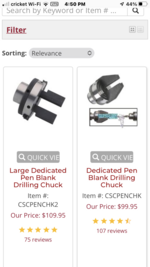

A method to drill a hole through the blank if it's not already pre-drilled

- A drill press with adequate swing OR

- a drill chunk + 4 jaw lathe chuck (demo -

https://technologystudent.com/equip1/mlathe4.htm)

- drill bits in the size the pen kit requires

- don't do like I started to do and buy a single drill bit for each kit. Just buy a full set of quality drill bits for english and metric off the bat.

A method to glue the brass tube in the kit into the blank.

- Lots of discussion as to which type of glue is best.

A method to trim the blank down to the size of the barrel

- Barrel trimmer being common, which then requires some method to use the trimmer (drill) and to hold the blank

- Lots of love here for Rick's sanding jig that can uses your tailstock and sandpaper mounted to a faceplate to square the end of the blank. Count me in as one of fans.

Turning

Woodturning tools themselves obviously, possibly called a chisel set

The bushings for the pen kit and the mandrel you chose (Most TBCs come with different types of bushings)

Sandpaper of progressive grits - I keep a range from 120 - 1500 on hand but generally only use 320/400/600 most of the time

Finishing - If you want to put a finish on your pen there are dozens of possibilities, but one of the most common that I've seen is the superglue (CA) finish (edit - CA is for wood)

CA glue of some sort - probably in multiple densities (thin/medium/thick).

- I like the 'few coats of thin thickness CA followed by a few coats of medium CA method. But even if you come to like using just one type of CA it's very useful to have the differing thickness available for general use.

Some method of applying the CA glue - paper towels, shop towels, the plastic bag the kit came in - all are possibilities

CA accelerator - quick spray to have the CA dry quickly so you aren't waiting a long time between coats to apply

Method to sand and smooth down the CA glue - micromesh sanding pads being the most common I've seen

Some form of even finer polishing compound, again, lots of options but plastic polish being common.

Assembly

Pen press of some sort.

- Guess what? Lots of conversation about how to do this too.

I'm using a dedicated pen press that can also be used to disassemble pens as I need.

Ancillary

Replacement ink - a lot of the ink that comes in the kits are pretty awful.

Small bags/boxes or something to put the pen in - a nice add on if you are going to gift it to someone.

Ancillary for repeat pen making (definitely NOT an inclusive list)

Digital calipers - useful for getting precise measurements. I'm surprised at how often I refer to mine nowdays.

Bushing storage - now is a good time to think about bushing storage method - if you plan on trying out lots of pen kit types you'll want to think about you want to store them. Don't be like me that went through 3 options before landing on one that works for me.

Tool sharpening

- lardy if you thought the lathe was expensive...

- Touch up - Sharpening honer/card for touch up

- Major sharpening - Slow speed bench grinder with CBN wheels is what I hear a lot about. Pricey though. I didn't know and got a regualr

dewalt and stone wheels. Works but will someday move to CBN (kinda wasting money in the process)

- Various jigs etc for aiding in sharpening. (some tools work best at specific angles and improperly sharpening them can impact that angle)

Dust collection. - something to take care of the all the dust and shavings before it gets into the laundry basket and you get the serious hairy eyeball from your partner.