The sled I use on the bandsaw at our shop is as simple as it could be. I only use it for crosscutting. I'm not sure I'd use a bandsaw for segmenting unless you are a wizard at getting clean, smooth cuts on a bandsaw, something I sure can't do!

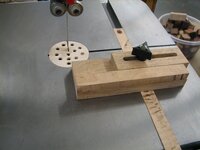

Simply take two pieces of scrap wood, plywood, or MDF about 8" long and 3-4" wide (I actually used PVC board since it was scrap). Screw them together long-sided to form a long "L" shape to form your crosscut sled.

Next, if you have a miter-gauge sled that most bandsaws/tablesaws come with, put it on the bandsaw and slide it up next to the blade (saw OFF). Screw your "L" base to the miter sled with one end of the "L" base just barely touching the blade. The sled is done!

I cut my blanks to length by placing the tube for the pen on the sled and putting a small clamp at the end of the tube (plus 1/8" for wiggle room). The clamp serves as my "adjustable stop". I then cut all the pen blanks that use that tube, and then put the next tube in, move the clamp/stop for the next tube.

The excess blank/drop falls off the left side of the blade.

This gives me very square cuts and I use it quite often.

If your bandsaw miter-gauge doesn't have holes in it for attaching jigs, you should be able to drill them easily enough.

I don't have a pic (sorry, my pen setup is across town so I can't take one right now).