Using the change gears in a mini lathe, the finest feed you can get is 256 threads per inch. This doesn't leave a very smooth finish. So, I set out to slow down the feed rate. I've combined a couple of ideas from others that have done a similar modification. Here is what I came up with, how I did it, the parts used, and the results.

I am driving the feed screw with a DC geared motor from the right side of the lathe. I've also added a variable speed drive that uses Pulsed Width Modulations (PWM). This essentially turns the motor on and off at set intervals (pulses) but still at the same DC voltage preserving the motors torque at lower speeds. The motor is 24 volts and 45 rpm unloaded. I used a 24 volt power supply, laptop power brick and cord. I added a double throw switch between of the variable speed drive and motor so I can reverse the voltage to the motor and reverse the direction. This allows me to feed in both directions with variable speeds.

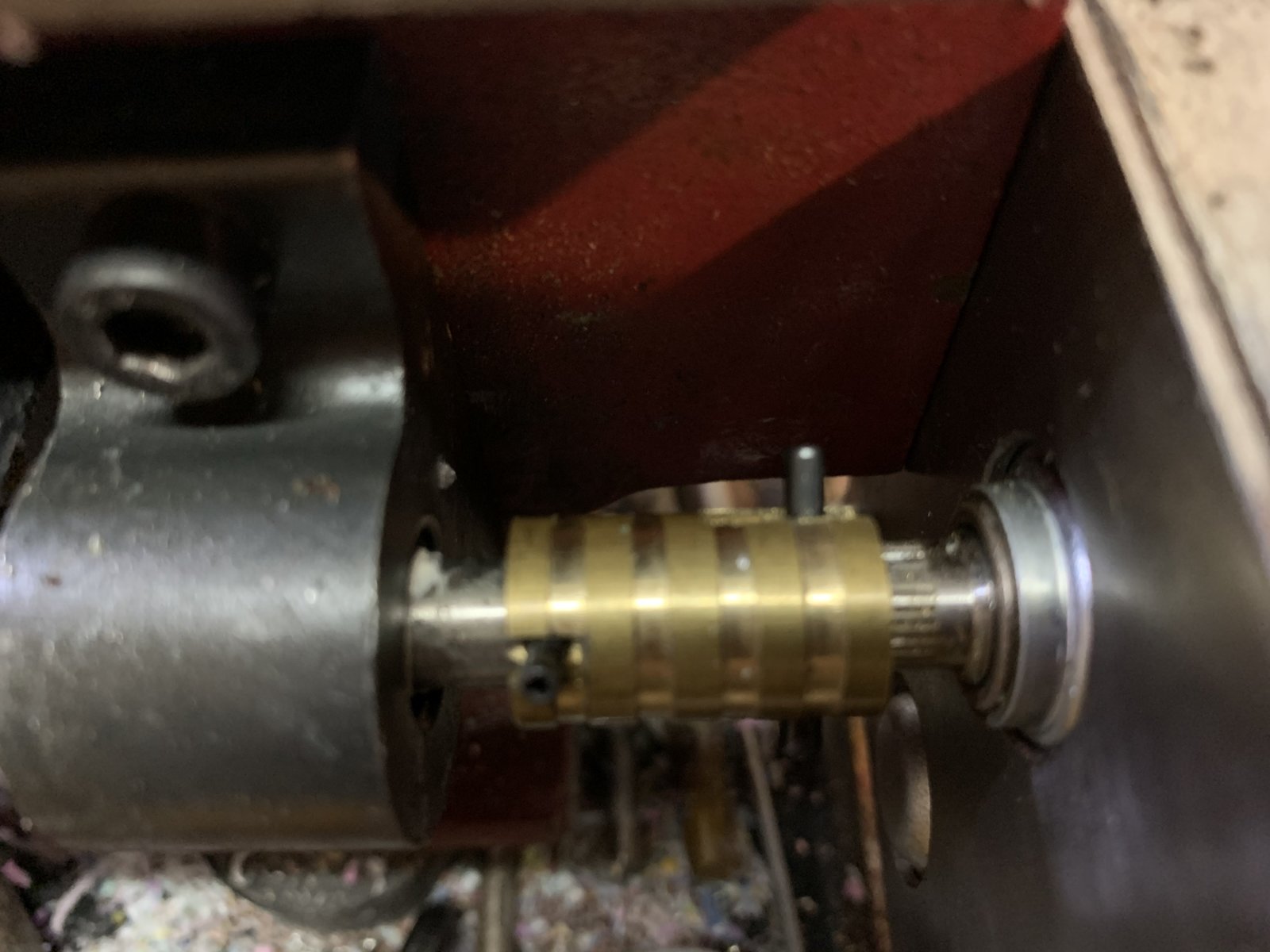

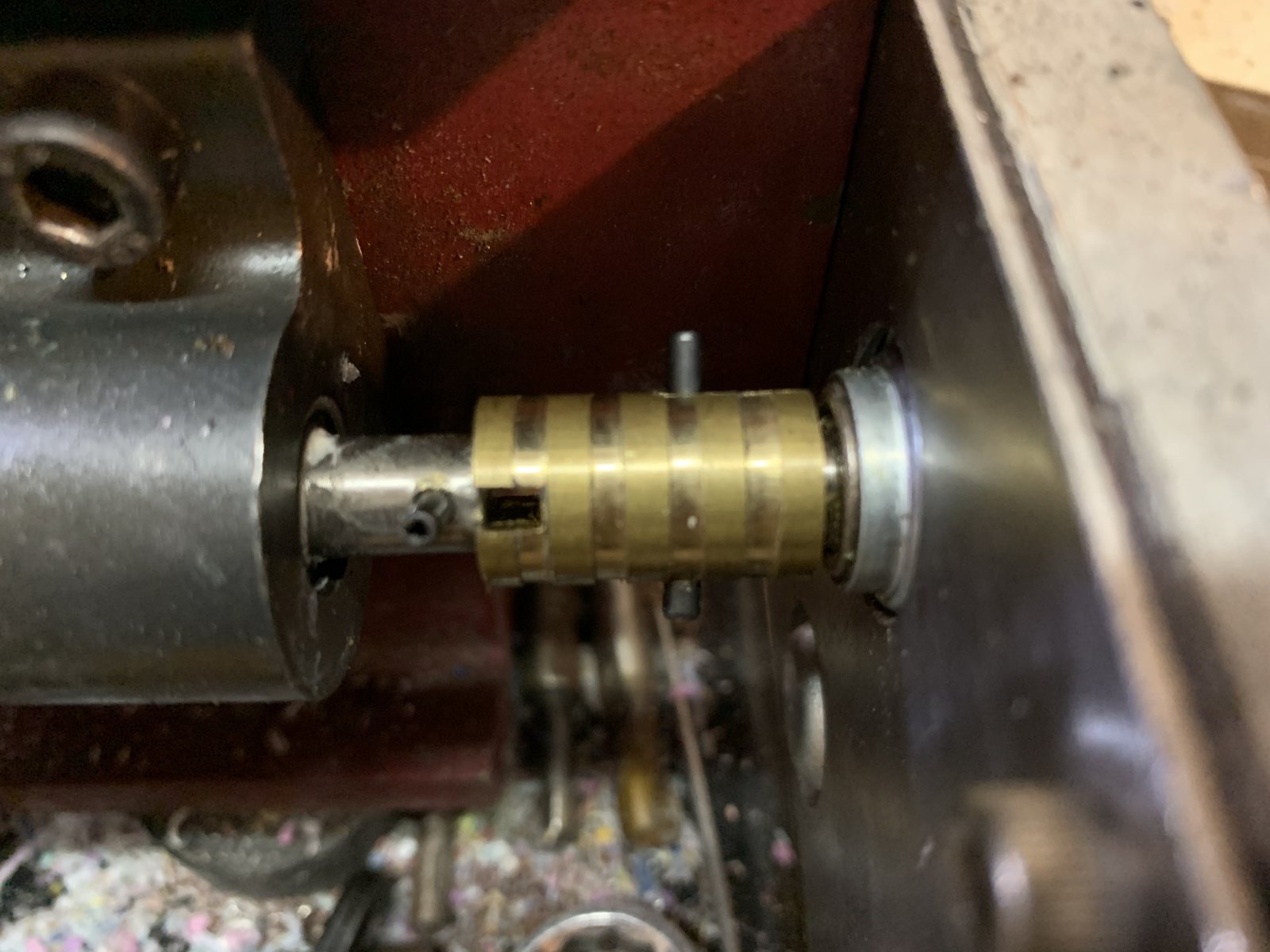

I had to modify the drive screw to be able to connect the motor. I removed the drive screw, drilled into the right end on the lathe and tapped for a M6 x 1.0 thread. I made a small shaft to thread into the drive screw, one end matching the motor shaft diameter and the other threaded M6 x 1.0. I used Blue LocTite when attacking it to the feed screw so it wouldn't back out when turning in reverse. I crossed drilled it with a 3/32" drill to take a 3/32" pin. I then cross drilled the motor shaft and added a 3/32" pin. To connect the two I used some 1/2" brass rod drilled slightly larger that the motor shaft. Using a cutoff wheel on my Dremel, I cut slits on each end to engage the pins. The one on the motor side was cut deep enough to allow you to pull back the coupler and disconnect from the feed screw.

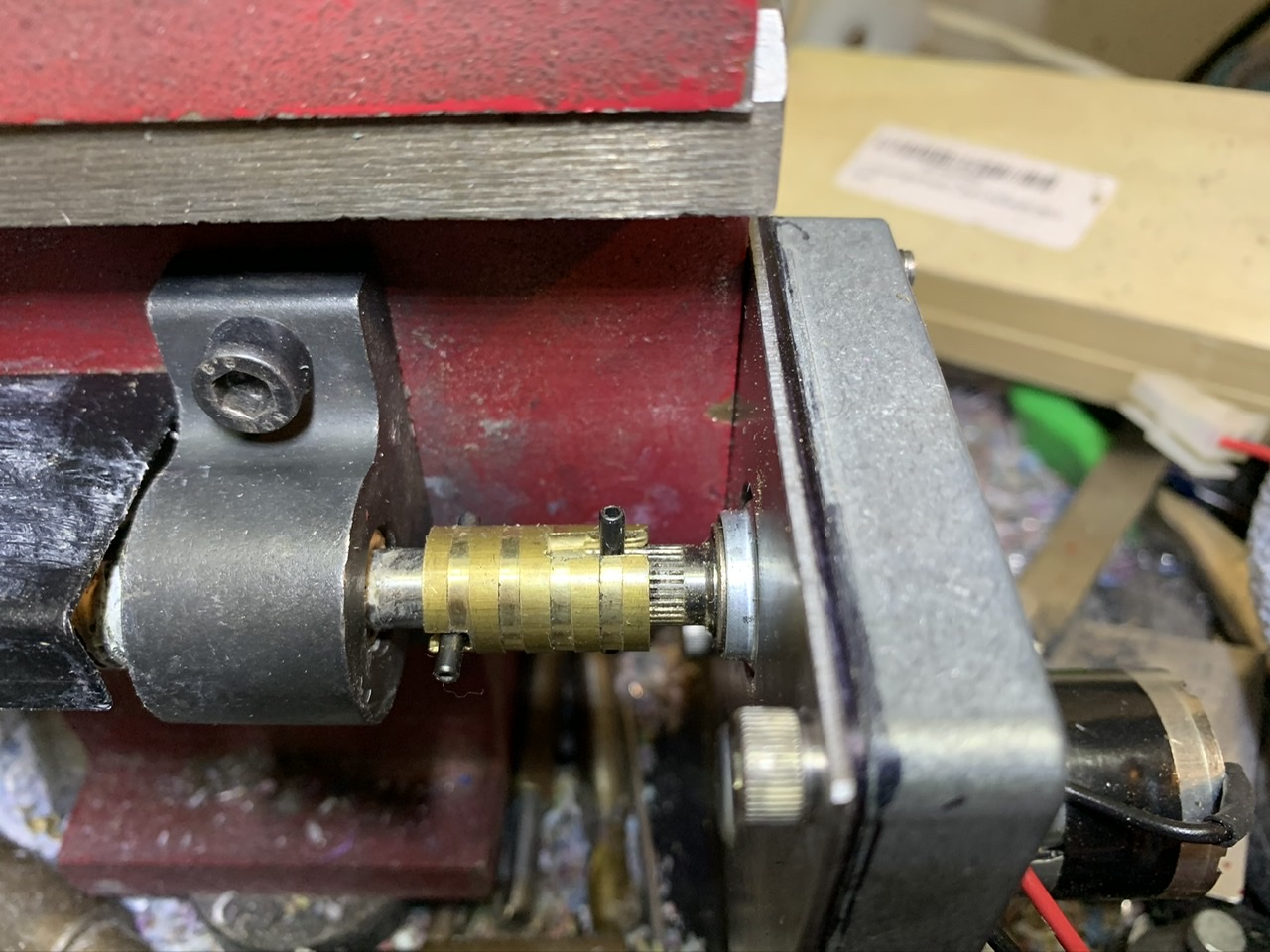

The motor is mounted using a piece of sheet steel screwed to the right side of the lathe bed. I started with a cardboard template to get the rough shape then cut out of the steel sheet. I attached the motor to the sheet, aligned the motor shaft to the feed screw using the brass coupler, and clamped the steel sheet to the end of the lathe bed. Make sure the alignment allows the coupler to easily slide back and forth. I then drilled two holes through the sheet and into the lathe bed then tapped the holes for mounting.

The variable speed controller comes with the potentiometer and an on off switch wired in. I installed it along with the switch for reversing in an electronic project box. Wired everything up, soldered the connections, and covered the connections with heat shrink tubing.

Danny

I am driving the feed screw with a DC geared motor from the right side of the lathe. I've also added a variable speed drive that uses Pulsed Width Modulations (PWM). This essentially turns the motor on and off at set intervals (pulses) but still at the same DC voltage preserving the motors torque at lower speeds. The motor is 24 volts and 45 rpm unloaded. I used a 24 volt power supply, laptop power brick and cord. I added a double throw switch between of the variable speed drive and motor so I can reverse the voltage to the motor and reverse the direction. This allows me to feed in both directions with variable speeds.

I had to modify the drive screw to be able to connect the motor. I removed the drive screw, drilled into the right end on the lathe and tapped for a M6 x 1.0 thread. I made a small shaft to thread into the drive screw, one end matching the motor shaft diameter and the other threaded M6 x 1.0. I used Blue LocTite when attacking it to the feed screw so it wouldn't back out when turning in reverse. I crossed drilled it with a 3/32" drill to take a 3/32" pin. I then cross drilled the motor shaft and added a 3/32" pin. To connect the two I used some 1/2" brass rod drilled slightly larger that the motor shaft. Using a cutoff wheel on my Dremel, I cut slits on each end to engage the pins. The one on the motor side was cut deep enough to allow you to pull back the coupler and disconnect from the feed screw.

The motor is mounted using a piece of sheet steel screwed to the right side of the lathe bed. I started with a cardboard template to get the rough shape then cut out of the steel sheet. I attached the motor to the sheet, aligned the motor shaft to the feed screw using the brass coupler, and clamped the steel sheet to the end of the lathe bed. Make sure the alignment allows the coupler to easily slide back and forth. I then drilled two holes through the sheet and into the lathe bed then tapped the holes for mounting.

The variable speed controller comes with the potentiometer and an on off switch wired in. I installed it along with the switch for reversing in an electronic project box. Wired everything up, soldered the connections, and covered the connections with heat shrink tubing.

Danny