eliasbboy

Member

I'm so frustrated now I'm about ready to sell my lathe!

I came home and went right out to sharpen my tools, something I've never really mastered. I first tried the Work Sharp 3000 and tool bar/Tormek combo and I was getting horrible results. The tool bar is level but as I marked both sides of my skew chisel with marker I could see I was getting lopsided results.

I switched over to my THIRD grinder (I've had issues) with the wolverine jig attached. I've tried 3 separate grinders, and 6 different grinding wheels. Every wheel I use seems to have some wobble to it no matter what I try.

My skew is now completely fooked, and my roughing gouge looks like Helen Kellen sharpened it- blind folded.

I'm a 38 year old father of two with a fairly successful family business that I've helped run since I was 15. I have an IQ in the 130's and I watch the Discovery Channel. How can the mystery of sharpening be so elusive? I could literally fold up shop right now.

Here's pics of my sharpening debacle. The tip of the chisel got too hot as I got aggravated. I left the burn marks like a Scarlet letter of shame. Feel free to mock. I'm impervious to pain right now.

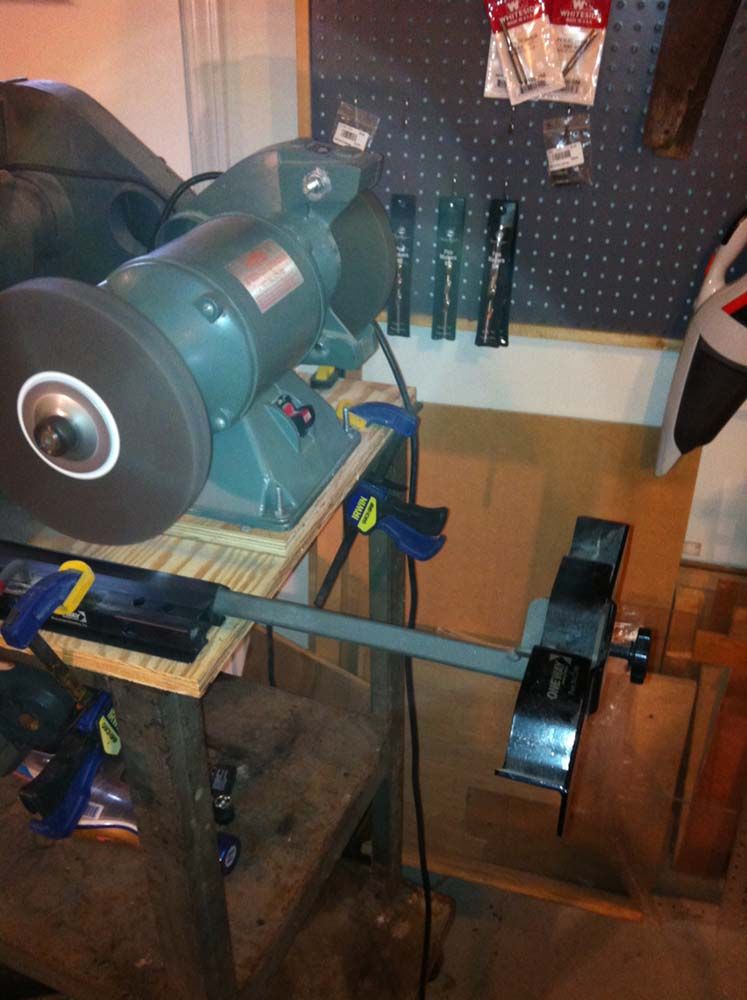

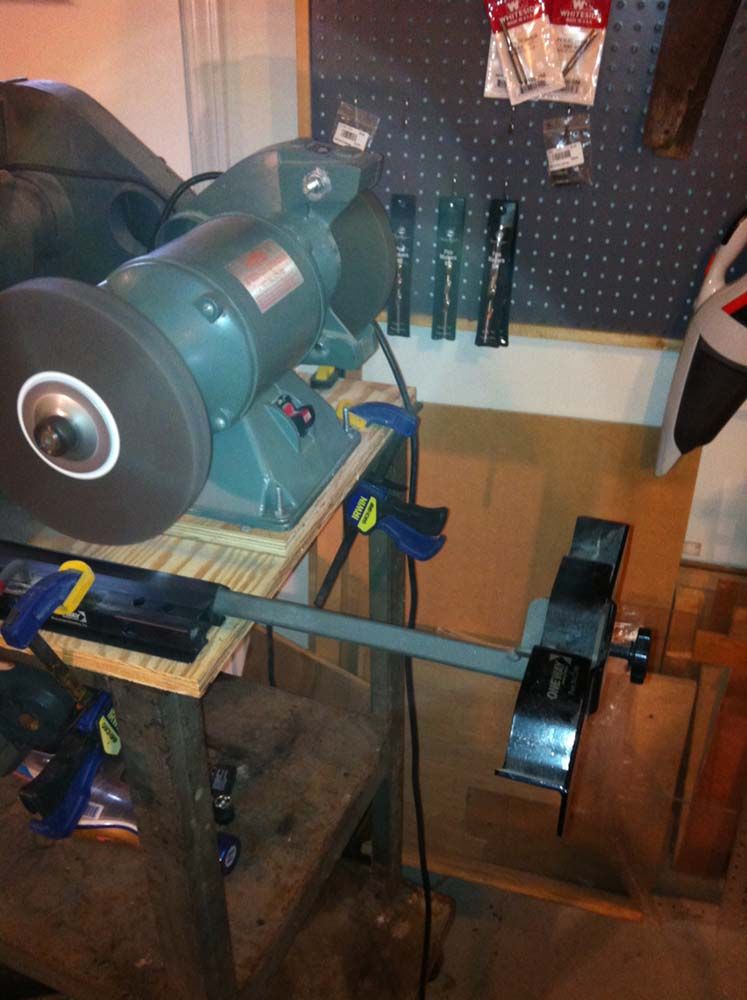

He is the evil grinder and jig that brought forth the curse.

The gouge is not straight across anymore. It's almost like I did this on purpose.

Please look for my upcoming coffee table book "How Not to Sharpen".

I came home and went right out to sharpen my tools, something I've never really mastered. I first tried the Work Sharp 3000 and tool bar/Tormek combo and I was getting horrible results. The tool bar is level but as I marked both sides of my skew chisel with marker I could see I was getting lopsided results.

I switched over to my THIRD grinder (I've had issues) with the wolverine jig attached. I've tried 3 separate grinders, and 6 different grinding wheels. Every wheel I use seems to have some wobble to it no matter what I try.

My skew is now completely fooked, and my roughing gouge looks like Helen Kellen sharpened it- blind folded.

I'm a 38 year old father of two with a fairly successful family business that I've helped run since I was 15. I have an IQ in the 130's and I watch the Discovery Channel. How can the mystery of sharpening be so elusive? I could literally fold up shop right now.

Here's pics of my sharpening debacle. The tip of the chisel got too hot as I got aggravated. I left the burn marks like a Scarlet letter of shame. Feel free to mock. I'm impervious to pain right now.

He is the evil grinder and jig that brought forth the curse.

The gouge is not straight across anymore. It's almost like I did this on purpose.

Please look for my upcoming coffee table book "How Not to Sharpen".

Last edited: