This is a great site and has the set-up for the jet mini...

http://alisam.com/page/14g9e/Woodworking_turning.html

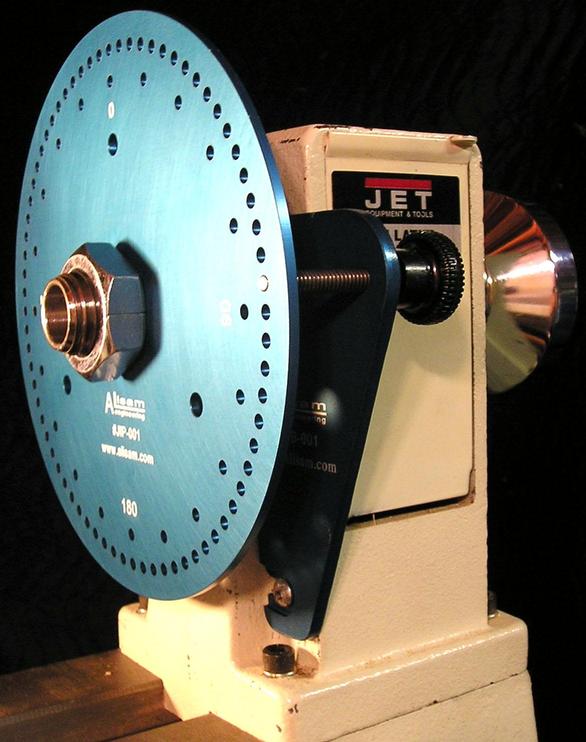

This new accessory from Alisam is a complete system for indexing on your "JET" 1014 mini-lathe! The system consists of a 7 inch, laser engraved, anodized aluminum plate with a 1 inch center ID spindle hole and two concentric rows of indexing holes. The outer row of 72 holes are spaced 5 degrees apart and the inner row of 20 holes are 18 degrees apart. This combination allows the user to adjust for virtually any position around the circumference of your turning! Also included is the custom bracket machined to utilize the existing tapped hole and bolt on the headstock of the JET mini-lathe. NO MODIFICATIONS TO YOUR LATHE REQUIRED! We also include a thumb scew for securing this bracket to the headstock, (in conjunction with the "Belt adjustment door" spring retention bolt on your JET lathe), a "dog point" indexing screw and a 1 inch X 8 tpi threaded jam nut to secure the indexing plate on your spindle. You may also secure the plate to the spindle with your lathe's chuck or faceplate. The bracket may be left in position without getting in the way of either your turning or belt adjustments when not using the index plate.

Customize your turnings quickly and easily just by aligning the indexing screw to any hole you choose and your ink, paint, router or carving tools add your personal artistic touch to your work!

$45.99

We have come across 2 JET lathes, (in almost three years of selling the JIS-01's), serial #C 3100625 & #C 4034937, where the headstock's tapped holes we use for securing our custom bracket were not where they were designed to be, even though JET's engineers told us the hole positions do not vary! We did design some play in our bracket to make up for some loose tolerances at the factory BUT obviously it is possible then to have a JET lathe that in the production run has the position of the tapped holes off. In such an instance it may be necessary to alter our bracket.

Alisam Engineering, PO Box 75, Lima, New York 14485

©Alisam Engineering 2008