chrisk

Member

Hi all,

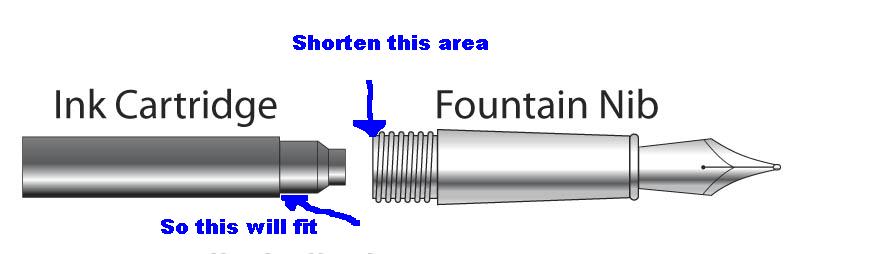

Tonight I offered a Jr Gent FP to a friend who generally uses converters. But I had a lot of trouble by trying to fit a Schmidt or a Heritance Vacuum converter on this FP kit. In the beginning, even by forcing the converter to fit, it remained stubbornly empty! At last I was able to fill a Schmidt one.

But it seems that those converters aren't compatible with the Jr Gents kits.

Do some colleagues had a similar experience?

Thanks in advance for any feedback.

Tonight I offered a Jr Gent FP to a friend who generally uses converters. But I had a lot of trouble by trying to fit a Schmidt or a Heritance Vacuum converter on this FP kit. In the beginning, even by forcing the converter to fit, it remained stubbornly empty! At last I was able to fill a Schmidt one.

But it seems that those converters aren't compatible with the Jr Gents kits.

Do some colleagues had a similar experience?

Thanks in advance for any feedback.