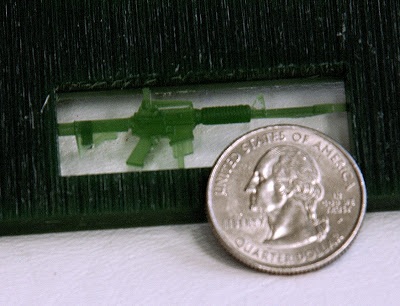

I was asked if I could make a clip of a M16. I was provided a picture and decided it was a fun thing to try to do, just to do it. I used the picture to design the clip and drew it in my cad program. I have about 10 hours just in the drawing of it. the pictures below show the clip milled out of wax and then cast in silver. I use a .1mm cutter to cut the wax, step over on the cutter is .0025mm. It makes the first cut and then moves over .0025 of a millimeter and makes another and so on until its done. It takes about 2 hours for the machine to cut the wax. from there it goes through the lost wax process and you can see the final results. Its 1 3/4 inches long and about 10mm tall. Enjoy.

the cast in silver piece.

the cast in silver piece.