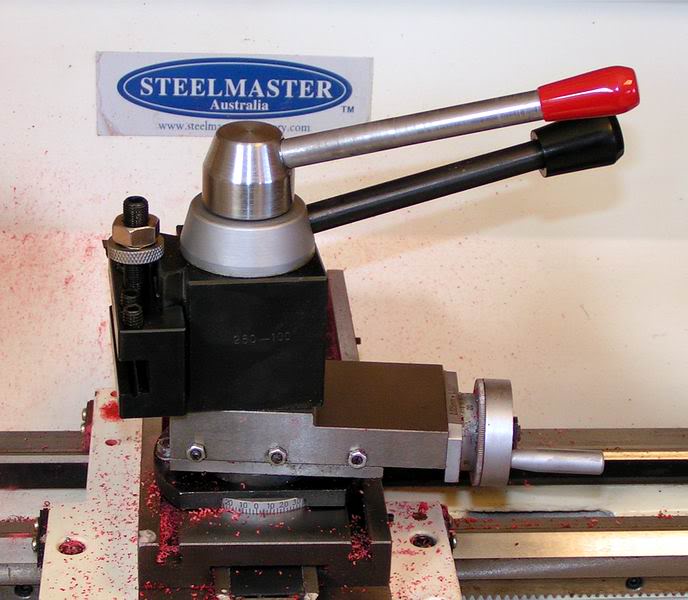

Very recently got a QCTP from Charlie ( that New London bloke:biggrin . I was fed up with the poxy little block one that was on my lathe. I knew from the beginning that I would have to mod either my topslide or the new tool post or both:frown: But I really didn't want to mod the topslide and I wanted to be able to re-fit the original, just in case. Many people just mount these directly on the cross slide, but I still wanted to be able to do tapering so it had to go on the top slide.

. I was fed up with the poxy little block one that was on my lathe. I knew from the beginning that I would have to mod either my topslide or the new tool post or both:frown: But I really didn't want to mod the topslide and I wanted to be able to re-fit the original, just in case. Many people just mount these directly on the cross slide, but I still wanted to be able to do tapering so it had to go on the top slide.

I just wanted to show these pics in case someone else is thinking of doing the same thing.

The existing TS has a 20mm dia bush but the QCTP only had a 16mm hole. So I simply bored it out.( For those that know how these things work, there was still plenty of meat for the inner sleeve to bear down on.)

Next was to alter the 16mm QCTP bolt to fit over the existing 10mm bolt.

Just measured, cut, drill and tapped.

And that was that :biggrin:

I still want to re-position the locking handle cos at the moment, the best setting I can get is about the 2.30 position. I'd like it to lock at the 4 o'clock spot. But for now, I'll just unscrew the handle if it gets in the way of the tailstock clamp.

This is probably 1 size too big for my machine but I couldn't resist the bargain price:biggrin:. It was easier to fit/mod than I imagined and I'm glad I didn't have to alter the lathe at all.

If any of the metal lathe guru's spot anything I did wrong, then please let me know:wink:

I just wanted to show these pics in case someone else is thinking of doing the same thing.

The existing TS has a 20mm dia bush but the QCTP only had a 16mm hole. So I simply bored it out.( For those that know how these things work, there was still plenty of meat for the inner sleeve to bear down on.)

Next was to alter the 16mm QCTP bolt to fit over the existing 10mm bolt.

Just measured, cut, drill and tapped.

And that was that :biggrin:

I still want to re-position the locking handle cos at the moment, the best setting I can get is about the 2.30 position. I'd like it to lock at the 4 o'clock spot. But for now, I'll just unscrew the handle if it gets in the way of the tailstock clamp.

This is probably 1 size too big for my machine but I couldn't resist the bargain price:biggrin:. It was easier to fit/mod than I imagined and I'm glad I didn't have to alter the lathe at all.

If any of the metal lathe guru's spot anything I did wrong, then please let me know:wink: