Dalecamino

Local Chapter Leader

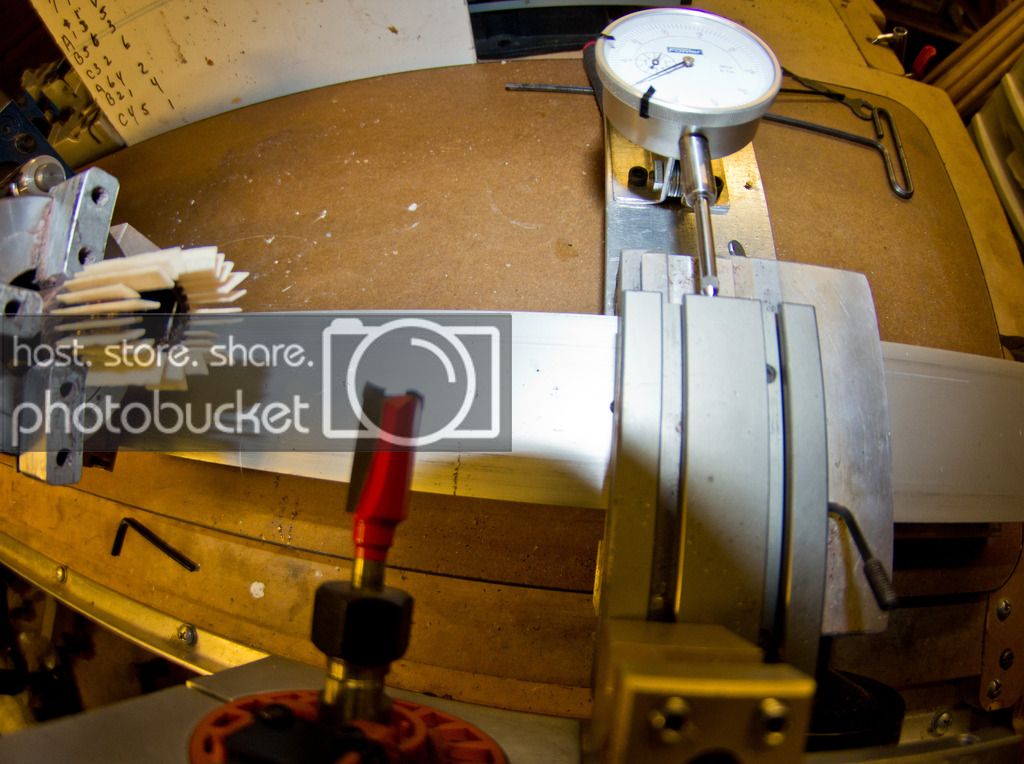

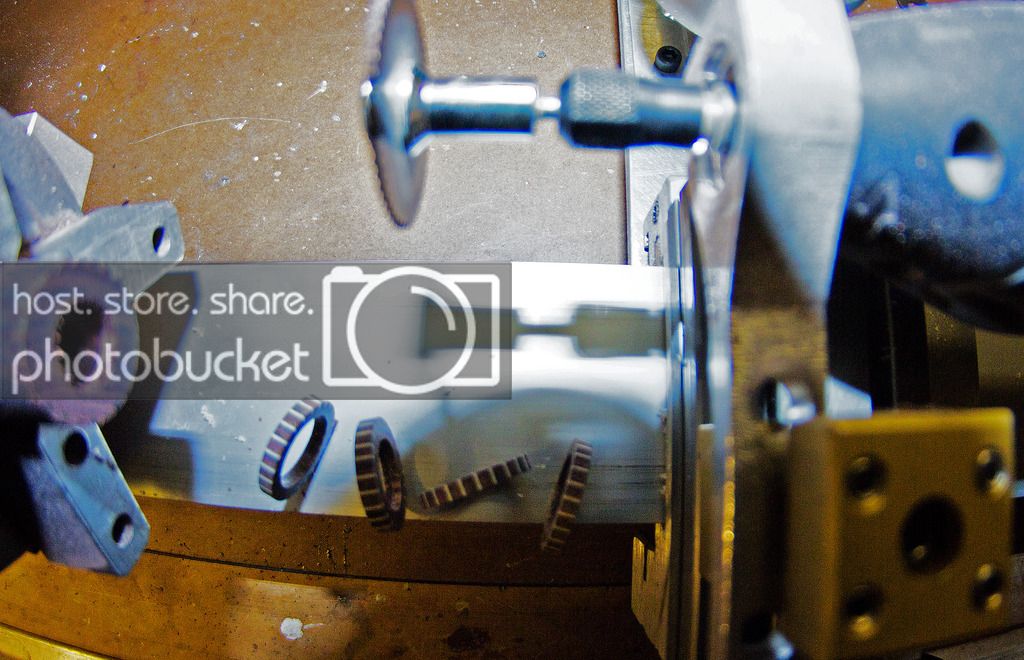

Some time ago, I saw this post by Steven Jackson (Skiprat) http://www.penturners.org/forum/f30/indexing-your-metal-lathe-125597/ Got my attention quick. After a couple emails with him I, contacted Mike Roux (bluwolf) who has a mill and, KNOWS how to use it. Asked Mike if he could help me out with fabricating a tool holder to, mount a router on my 7x16 MicroMark lathe? He went all the way with it. Bought the router so, he could fit everything together and, shipped it all to me. Here are some photos of the tool.

Once I received it, I took quite a long time deciding how I was going to go about getting the lathe set up to use it for indexing and, whatever else I would do with it. SO....after more emails and, phone calls to Mike, I got started.

First I chucked a 3/4" socket in the headstock. Put a 1/2"x11/2" bolt in the tailstock and, ran the tailstock up so the bolt fit into the socket. Then mounted a 1/4" thick steel plate on top of the gear cover and, centered the hole for the indexing pin over the backing plate flange. I used a transfer punch to make starter holes for my drill. Once I got them all marked I, went around again with my drill. Then, I tapped threads in the hole for the indexing pin. My first project using this was, turning a knob from a bottle stopper blank I had which, just happened to have some aluminum shavings or, foil I think it is. I used the router to cut grooves in the sides for grip. It work out great. Now I'll need to make something else, a little more serious.

Sorry, all the photos are run together and, not full sized. I guess this old dog needs to learn how the site works.

Thanks to Steven and, Mike for your support. You guys are awesome!:wink:

Once I received it, I took quite a long time deciding how I was going to go about getting the lathe set up to use it for indexing and, whatever else I would do with it. SO....after more emails and, phone calls to Mike, I got started.

First I chucked a 3/4" socket in the headstock. Put a 1/2"x11/2" bolt in the tailstock and, ran the tailstock up so the bolt fit into the socket. Then mounted a 1/4" thick steel plate on top of the gear cover and, centered the hole for the indexing pin over the backing plate flange. I used a transfer punch to make starter holes for my drill. Once I got them all marked I, went around again with my drill. Then, I tapped threads in the hole for the indexing pin. My first project using this was, turning a knob from a bottle stopper blank I had which, just happened to have some aluminum shavings or, foil I think it is. I used the router to cut grooves in the sides for grip. It work out great. Now I'll need to make something else, a little more serious.

Sorry, all the photos are run together and, not full sized. I guess this old dog needs to learn how the site works.

Thanks to Steven and, Mike for your support. You guys are awesome!:wink:

Attachments

-

chuckrouter (1).jpg239.2 KB · Views: 314

chuckrouter (1).jpg239.2 KB · Views: 314 -

chuckrouter (2).jpg176.9 KB · Views: 358

chuckrouter (2).jpg176.9 KB · Views: 358 -

chuckrouter (3).jpg173.8 KB · Views: 370

chuckrouter (3).jpg173.8 KB · Views: 370 -

chuckrouter (4).jpg122.4 KB · Views: 349

chuckrouter (4).jpg122.4 KB · Views: 349 -

IMG_1623.jpg207.3 KB · Views: 305

IMG_1623.jpg207.3 KB · Views: 305 -

IMG_1624.jpg202.8 KB · Views: 309

IMG_1624.jpg202.8 KB · Views: 309 -

IMG_1625.jpg205.9 KB · Views: 322

IMG_1625.jpg205.9 KB · Views: 322 -

IMG_1626.jpg209.5 KB · Views: 307

IMG_1626.jpg209.5 KB · Views: 307 -

IMG_1627.jpg232 KB · Views: 382

IMG_1627.jpg232 KB · Views: 382 -

IMG_1635 (2).jpg184.2 KB · Views: 405

IMG_1635 (2).jpg184.2 KB · Views: 405