Fireengines

Member

I am looking to purchse a new scroll saw under $150.00 and need recomendations.

Thanks!

Thanks!

I got the Porter Cable from Lowes. Right now it's a bit more, but the big thing you want to make sure is it take the pin and non pin blades.

I'd check a pawn shop too. There might not be anything interesting, but what does it cost to look?

I'm curious about the massive aversion to the pin type blades. I'm even less than a newbie with a scroll saw, but changing a blade on my old Craftsman takes about 15 seconds, I'd guess. Is there a difference in cut quality or is it the blade change process?

I'm certain I don't have the skills to do anything that a real scroller can do, but I still have fun using mine from time to time.

Sandy.

I'd check a pawn shop too. There might not be anything interesting, but what does it cost to look?

I'm curious about the massive aversion to the pin type blades. I'm even less than a newbie with a scroll saw, but changing a blade on my old Craftsman takes about 15 seconds, I'd guess. Is there a difference in cut quality or is it the blade change process?

I'm certain I don't have the skills to do anything that a real scroller can do, but I still have fun using mine from time to time.

Sandy.

Amazon lists them for $499 at nearly half-price (list $990).

Don't think you can go wrong so long as you test it and it runs.

I've found a DEWALT DW788 20-in Variable Speed Scroll Saw for $200.00 and it looks new. Deal or no deal?

This is not to steer anyone away from this saw, but my problem with this saw was the design of the way the table is mounted to the body. A buddy of mine bought one and when I test drove it while cutting out a quarter,I noticed a lot of slop(loose), even after everything was all tightened down. Now call me stupid, but when I compared the tables design with my Dremel scroll saw,I noticed that the Dremel was braced with a different type of bracket that doesn't allow the table top to move side to side in the least bit. Oh how I wish Dremel still made their scroll saws.

OK folks, here is the information:

It is a Type one. Serial number 29575. 13 amp 400-1750spm. Dewalt DW 788.

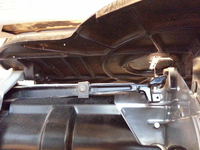

I will take a look at the saw this week. However, I've asked for some additional photos. This machine looks like it is missing some parts (foot, air nozzle, and the bar that connects the foot).

The other one I've found is a Type 2 with a stand. This one is from a company in the city that repairs scroll saws and he has offered to spend a hour with me explaining the machine and how to adjust it.

Just and FYI...

Ended up getting the Type 1 for $175.00.