chrisk

Member

Hi all,

After I purchased, two years ago, a carbide pen mill from Nolan, and after I learned the shop where these were made had closed, I was upset for after trying this tool one cannot live without it...

Last year I had the opportunity to give my pen mill for honing here in Greece. The job was well done for, with this hell of a tool, I was even able to perfectly clean my pen blanks (believe me or not...) after finishing them with CA! Meanwhile, I tried to order a new carbide pen mill from different sources. After some unsuccessful attempts and a poorly made pen mill (3d on the right with positive rake) I found a firm here in Greece which IMHO will be able to make carbide pen mills to our specifications.

I already ordered two units from them and a fast test (with a spalted beech blank) produced some interesting results. These units were made from scratch, that is I didn't provide the mills. The mill's diameter is 7/8" (22mm) and the welded carbide cutters have a neutral rake.

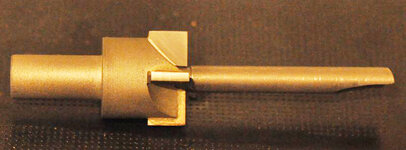

On the pic hereunder the first pen mill (left) is my Nolan's one (a hell of a tool!!!) with negative rake cutters, the second one (center) is one of the pen mills made by the Greek firm (neutral rake) and the last (right) is a pen mill, with positive rake, made by a Belgian firm.

The question is, is there any interest for this kind of carbide pen mills? I have to meet the person in charge at the end of August but he already told me they can make this kind of mills either from scratch (to our specifications with neutral or negative rake, at the diameter we want...) either by welding the carbide cutters to mills we'll provide.

After I purchased, two years ago, a carbide pen mill from Nolan, and after I learned the shop where these were made had closed, I was upset for after trying this tool one cannot live without it...

Last year I had the opportunity to give my pen mill for honing here in Greece. The job was well done for, with this hell of a tool, I was even able to perfectly clean my pen blanks (believe me or not...) after finishing them with CA! Meanwhile, I tried to order a new carbide pen mill from different sources. After some unsuccessful attempts and a poorly made pen mill (3d on the right with positive rake) I found a firm here in Greece which IMHO will be able to make carbide pen mills to our specifications.

I already ordered two units from them and a fast test (with a spalted beech blank) produced some interesting results. These units were made from scratch, that is I didn't provide the mills. The mill's diameter is 7/8" (22mm) and the welded carbide cutters have a neutral rake.

On the pic hereunder the first pen mill (left) is my Nolan's one (a hell of a tool!!!) with negative rake cutters, the second one (center) is one of the pen mills made by the Greek firm (neutral rake) and the last (right) is a pen mill, with positive rake, made by a Belgian firm.

The question is, is there any interest for this kind of carbide pen mills? I have to meet the person in charge at the end of August but he already told me they can make this kind of mills either from scratch (to our specifications with neutral or negative rake, at the diameter we want...) either by welding the carbide cutters to mills we'll provide.