I buy PR in 5 gallon buckets. ... SO...$2.00 materials, $1.00 labor and .25 for power. That puts my blanks cost $3.25 each. This is as close as I can get it. Of course, no start up costs like molds, containers, stir sticks and "machinery" are figured into this number.

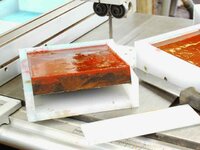

Can you pour into sheets and slice them into blanks on the bandsaw? I have never poured PR, but I was wondering if I could pour a 3/4" thick slab and slice it into 3/4 square x 5" long? Will it cure properly in a slab?

Will that save any money? Most of the PR blanks I buy are in the $2-$5 range at places like Penn State and Woodcraft. Doesn't seem feasible to pour my own at an average $3.25 + start-up costs + expendibles. Then there's the hassel and mess and clean-up costs not included.

Hi Cincinnati,

Yes you can, it does save a lot of time, it require less material to make the molds with and there is also a slight saving in PR.

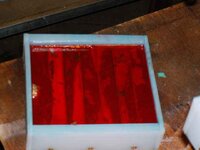

I started with single molds (pic attached) and not soon after I made bigger molds witch can accommodate 6 to 7 blanks, the pot will accommodate 3 of these molds in a specially made timber separator/shelving type so, one pour will be a 18 to 21 blanks each time. It is possible to create 3 different colours and swirl/pour techniques (final effects) one on each mold but and unless you have everything ready and are well set up, I would suggest you to do 1 mold at the time if you want them all different from each other, otherwise the resins will set too much to be pressurized effectively into all crevasses in the wood, and the resin would stick to the wood either...!

Set up cost will be about $400 to $500, including the first gallon of resin and a couple of colours/powders. There is a fair amount of money involved in getting all the pouring and measuring pots, acetone, and many, many other small stuff that you will need such as gloves, etc., and I only can say in relation to PenMan1 per blank cost estimate that he is pretty right about it, I have set my Resifill prices @ AU$3.50 each just to cover the cost of producing them and the PR here in Australia in considerably more expensive than in the US (AU$70+freight per gallon), I use a little more power than that and all my calculation here based in production costs such as pouting materials, electricity, bandsaw blades (pretty bad on blades these resin blanks) and AU$1.00 for each piece of wood (part blank) used in the casting, regardless if is pine or the best grade Olive wood or burled woods.

There was no labour value added to the calculations, and they still sell for the same price today (most of them), while all the casting materials have add an increase of 12% since last year...! Money making machine, far from it, I do though, use bits of wood that wouldn't have any other use regardless of good grain and colours they may have, and I make some nice stuff for myself too...! I make plenty because I cut plenty of woods so my constant supply of wood casting material is endless and impressive to say the least, the many, many boxes of wood from my now 47 timber species casting material stored, speak from themselves...!

I will never, never used them all even if I live to the age of 100 and I still cut nearly every day...!

Apart from the health risks of being exposed to such toxic products, casting is indeed a lot of fun, particularly when we get to see what we did...!

Cheers

George