You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

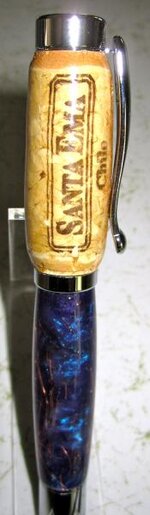

wine cork cap

- Thread starter Jjartwood

- Start date

Signed-In Members Don't See This Ad

See more from Jjartwood

What kit is this?

Michael

Very interesting pen and anything made with those "branded" wine corks are always nice to see but, what caught my attention is the "stuff" you've got mixed up in the resin, what in a heck is that, brass wire...????

Well done,

Cheers

George

Your secrets safe with me Brother. I guess I need to stop drinking cheap "Table Wine" so I can get a nice cork w/ a fancy design.

I may enlight you on that question as I often collect stamped wine corks, to supply to some mates that like them for pens and, I can say that, being in one of the biggest wine making areas of Australia, there are only a few wineries that still use cork as the rest, all went to the plastic caps. Not all brand their corks but those that do, have then stamped which means that the ink is very superficial, and will take little effort to rub it off with sandpaper or on a lathe...!

I know that some guys, spend the time and effort to actually "skin" the cork, there is, cut the outside layer and then glue it to the brass tube, and if dome properly, the joint is almost invisible, as soft cork material assists with the pressing of the two ends to a seamless join...!

Hope this helps...!

Cheers

George

Great info George. I may have to try that, though I am not used to skinnin' what I can't eat.

Yes John, that would be a easier way to "shrink" the cork to the size you want (kit type) however, I've done them also by using a dine scroll saw blade and cut the outer layer of the cork, nearly paper thin, this way the tube can be dressed with the stamped part of the corn (normally half or less of the cork diameter), and then cast it in crystal clear resin, like so many other barrels are done, with all sorts of stuff glued to the tube.

I have also used a "plug cutter" bit to remove most of the cork centre, this require a wood made little jig where the cork is sandwiched in tight so that it doesn't spin or blow apart. The problem that I noticed with these type of cork "shrinking" processes is that, the stamp, either a design/logo or words, tend to get a little distorted, which is some cases will spoil the original logo looks...!

While I like to work with natural or pressed cork, it can be sometimes a little temperamental, if you don't know what to expect from it but nevertheless, a great looking material...!

Cheers

George

Signed-In Members Don't See This Ad

Jgrden

Member

Jgrden

Member

I agree. Let's drink more wine. By the way, that is a $350.00 fountain pen in my shop.

Last edited:

RustySplinters

Member

Its always an excuse to have a wine or to remind that special friend to quit wine-ing

What kit is this?

Michael

robutacion

Member

Its always an excuse to have a wine or to remind that special friend to quit wine-ing

Very interesting pen and anything made with those "branded" wine corks are always nice to see but, what caught my attention is the "stuff" you've got mixed up in the resin, what in a heck is that, brass wire...????

Well done,

Cheers

George

Jjartwood

Member

The kit is an Atrax very flexable to most style,

Yes the cap is a little large for my style also but I made it for a friend who cut the top of his left thumb off and a fat cap is much easier for him to open

The blank is scrap speaker wire that I threw into some resin it did come out kind of cool.

Even a blind dog finds a bone now and again

Yes the cap is a little large for my style also but I made it for a friend who cut the top of his left thumb off and a fat cap is much easier for him to open

The blank is scrap speaker wire that I threw into some resin it did come out kind of cool.

Even a blind dog finds a bone now and again

Justturnin

Member

Looks great. Your friend will love it.

Question, If the logo is printed on the outside of the cork how could one turn the cork down but maintain the label? Does it go into the cork a ways that you would be able to take some off and it still show?

Question, If the logo is printed on the outside of the cork how could one turn the cork down but maintain the label? Does it go into the cork a ways that you would be able to take some off and it still show?

Jjartwood

Member

Actually ( and please don't tell anyone else ) I drilled the cork,and worked it down from

the inside,No turning other than the end blends.

the inside,No turning other than the end blends.

Justturnin

Member

Actually ( and please don't tell anyone else ) I drilled the cork,and worked it down from

the inside,No turning other than the end blends.

Your secrets safe with me Brother. I guess I need to stop drinking cheap "Table Wine" so I can get a nice cork w/ a fancy design.

Drstrangefart

Member

It's these two pens that have been shown here that remind me that I can't get too secure with my work, as a lot of it is amateur hackjobs with basic supplies. The Jjartwood and Jgrden pens are legitimate artisanship.

robutacion

Member

Looks great. Your friend will love it.

Question, If the logo is printed on the outside of the cork how could one turn the cork down but maintain the label? Does it go into the cork a ways that you would be able to take some off and it still show?

I may enlight you on that question as I often collect stamped wine corks, to supply to some mates that like them for pens and, I can say that, being in one of the biggest wine making areas of Australia, there are only a few wineries that still use cork as the rest, all went to the plastic caps. Not all brand their corks but those that do, have then stamped which means that the ink is very superficial, and will take little effort to rub it off with sandpaper or on a lathe...!

I know that some guys, spend the time and effort to actually "skin" the cork, there is, cut the outside layer and then glue it to the brass tube, and if dome properly, the joint is almost invisible, as soft cork material assists with the pressing of the two ends to a seamless join...!

Hope this helps...!

Cheers

George

Justturnin

Member

Looks great. Your friend will love it.

Question, If the logo is printed on the outside of the cork how could one turn the cork down but maintain the label? Does it go into the cork a ways that you would be able to take some off and it still show?

I may enlight you on that question as I often collect stamped wine corks, to supply to some mates that like them for pens and, I can say that, being in one of the biggest wine making areas of Australia, there are only a few wineries that still use cork as the rest, all went to the plastic caps. Not all brand their corks but those that do, have then stamped which means that the ink is very superficial, and will take little effort to rub it off with sandpaper or on a lathe...!

I know that some guys, spend the time and effort to actually "skin" the cork, there is, cut the outside layer and then glue it to the brass tube, and if dome properly, the joint is almost invisible, as soft cork material assists with the pressing of the two ends to a seamless join...!

Hope this helps...!

Cheers

George

Great info George. I may have to try that, though I am not used to skinnin' what I can't eat.

Jjartwood

Member

speaking only for myself Doc,your technique is quite sound,instead of building something I

like into a pen (and I hope this makes sense) I take what I like and try to build the pen around it. The operative word in " The Show off your pen "sight is Show off.

What I do not post (again speaking for myself ) is the 5 gal. bucket full of the "this sucks,start over stuff " But none the less thank you for the complement

Mark

ON a further note:George brings up a good point,plastic corks,I have found that asking the waitress in a fine restaurant and a good

tip will get you some pretty interesting corks

this is a variant of the technique that I used on the "less gift shop more sea port" pen cap

like into a pen (and I hope this makes sense) I take what I like and try to build the pen around it. The operative word in " The Show off your pen "sight is Show off.

What I do not post (again speaking for myself ) is the 5 gal. bucket full of the "this sucks,start over stuff " But none the less thank you for the complement

Mark

ON a further note:George brings up a good point,plastic corks,I have found that asking the waitress in a fine restaurant and a good

tip will get you some pretty interesting corks

this is a variant of the technique that I used on the "less gift shop more sea port" pen cap

Last edited:

Jgrden

Member

No skinning the cork. The trick is to make it the right size by working inside out, using the correct lathe speed and the correct Brad bit. Then it needs to be sized to the component tube.

robutacion

Member

No skinning the cork. The trick is to make it the right size by working inside out, using the correct lathe speed and the correct Brad bit. Then it needs to be sized to the component tube.

Yes John, that would be a easier way to "shrink" the cork to the size you want (kit type) however, I've done them also by using a dine scroll saw blade and cut the outer layer of the cork, nearly paper thin, this way the tube can be dressed with the stamped part of the corn (normally half or less of the cork diameter), and then cast it in crystal clear resin, like so many other barrels are done, with all sorts of stuff glued to the tube.

I have also used a "plug cutter" bit to remove most of the cork centre, this require a wood made little jig where the cork is sandwiched in tight so that it doesn't spin or blow apart. The problem that I noticed with these type of cork "shrinking" processes is that, the stamp, either a design/logo or words, tend to get a little distorted, which is some cases will spoil the original logo looks...!

While I like to work with natural or pressed cork, it can be sometimes a little temperamental, if you don't know what to expect from it but nevertheless, a great looking material...!

Cheers

George