pete00

Member

A few folks emailed and wanted to know how i did my desk top thing-a-ma-gig, now know as PDT (petes desk top thing a ma gig) So here’s the general idea. This is how i did it, there may be eaiser,safer,faster ways.

DANGER

Never having cut small pieces like this before it was a learning experience. A few badly designed jigs caused kickbacks and pieces of Corian flying everywhere. I ended up wearing a full face shield and gloves.

It helps if your table saw or miter saw has a zero clearance insert (no space between blade and side) After cutting material turn off power to blade and let blade stop before backing up or taking out material. I don’t have band saw, but all this should apply as well.

After using this setup and jig to cut the material, there were no more pieces flying and no kickbacks, so I took off my suit of armor. Just keep face shield.

From one piece of 4x4x1/2 “ tile you can make

One PDT and pen, with or with out business card holder

Or Two slim line pens

Basic steps

cut off two ½ inches pieces for pen from tile.

make pen first, if you drill through side you can cut off another piece. Then make base smaller. Not that I ever did that. Cut, trim, drill and make pen

I left sides of the base with factory rounded over edge

If you using square stock round over edge, if you want.

If you’re making the smaller version, no business card, cut sides off at 45 deg.

Keep cutting small slices off sides until you like the way it looks.

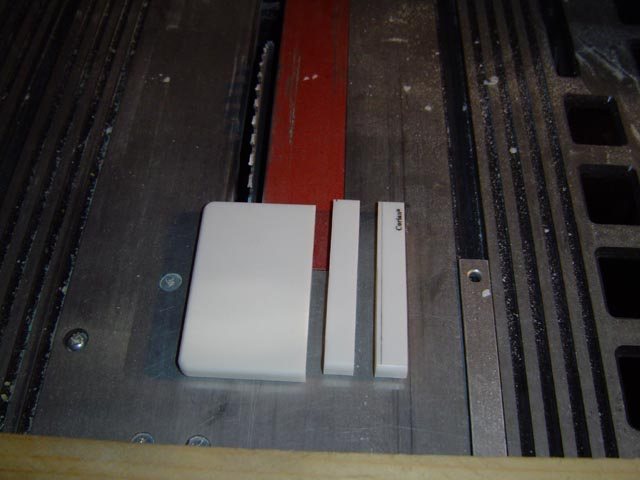

Cut a 1/8 slot for business card, ¼ inch deep, and about 1/8 inch from ends. I used a plunge cut with router table. Thats a business card on top of tile to help measure. Side stops help control length of cut. Center line on back board is where drill bit is.

For small pen holder cut 10mm hole, 1/4to 3/8 inch in from the top, any lower and it may drill through.

Test depth with gauge, if you push pen holder in while testing fit, it will stick. You need small strong wire with hook on end to lift it out. DON’T pry it up on outside with screwdriver you’ll mark up surface, and then you’ll need to sand and buff, not that I did that.

If all went well your ready to cut the bottom.

Set miter saw to 10 degree angle. Put in miter saw jig.

Youll have to do a few test cuts with scrap wood to find out where it cuts and to see if piece lays flat on surface. Adjust in and out until its doesnt rock, then save for future cutting. Make sure your test wood is the same thickness and length as your finished tile.

Otherwise you'll spend a day trying to figure out why nothing fits.

Not that i did that.

Bring blade up against jig to fine tune the position of the blade. Use scrap piece to test cut, if all is well save this piece for later use in setting up the jig. Put in block of Corian back side out, cut side on top. Use piece of wood on side of Corian to act as a stop and push stick.

Use light pressure while bringing down blade. Use scrap piece of wood first to check cut and then mark the top so you know what side to cut. No fun cutting wrong side and watching the hole fall off, not that ive done that.

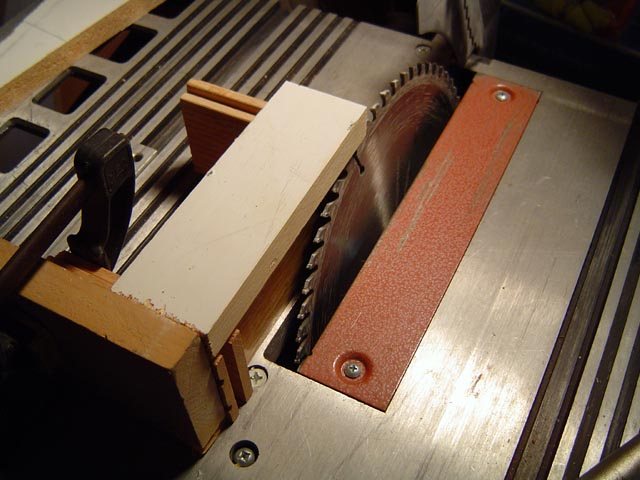

Using Table saw

On my saw I set the blade angle to 8 deg. I used the same jig but added a top and a back screwed on to hold things in place. After cutting let blade stop turning before you back up and remove stock.

Sand and buff as needed, sand off sharp edge as well. I use drill press with soft sanding disk covered with rag and Novus2.

Glue pen holder in hole, USE SMALL SMALL drop on side of holder, or bottom of hole. If you use more, the glue will come back out the hole and spread all around the outside of the pen holder. This is almost impossible to get rid of without scratching and buffing away gold plating, not that ive done that.

One PDT kit packaged, waiting to build

Buff pen and base.assemble.one whole family of PDTs...i done that !

Hope it helped and you have fun making these, I did. If you don’t have a saw let me know ill cut some for you, so you too can play.

pete

DANGER

Never having cut small pieces like this before it was a learning experience. A few badly designed jigs caused kickbacks and pieces of Corian flying everywhere. I ended up wearing a full face shield and gloves.

It helps if your table saw or miter saw has a zero clearance insert (no space between blade and side) After cutting material turn off power to blade and let blade stop before backing up or taking out material. I don’t have band saw, but all this should apply as well.

After using this setup and jig to cut the material, there were no more pieces flying and no kickbacks, so I took off my suit of armor. Just keep face shield.

From one piece of 4x4x1/2 “ tile you can make

One PDT and pen, with or with out business card holder

Or Two slim line pens

Basic steps

cut off two ½ inches pieces for pen from tile.

make pen first, if you drill through side you can cut off another piece. Then make base smaller. Not that I ever did that. Cut, trim, drill and make pen

I left sides of the base with factory rounded over edge

If you using square stock round over edge, if you want.

If you’re making the smaller version, no business card, cut sides off at 45 deg.

Keep cutting small slices off sides until you like the way it looks.

Cut a 1/8 slot for business card, ¼ inch deep, and about 1/8 inch from ends. I used a plunge cut with router table. Thats a business card on top of tile to help measure. Side stops help control length of cut. Center line on back board is where drill bit is.

For small pen holder cut 10mm hole, 1/4to 3/8 inch in from the top, any lower and it may drill through.

Test depth with gauge, if you push pen holder in while testing fit, it will stick. You need small strong wire with hook on end to lift it out. DON’T pry it up on outside with screwdriver you’ll mark up surface, and then you’ll need to sand and buff, not that I did that.

If all went well your ready to cut the bottom.

Set miter saw to 10 degree angle. Put in miter saw jig.

Youll have to do a few test cuts with scrap wood to find out where it cuts and to see if piece lays flat on surface. Adjust in and out until its doesnt rock, then save for future cutting. Make sure your test wood is the same thickness and length as your finished tile.

Otherwise you'll spend a day trying to figure out why nothing fits.

Not that i did that.

Bring blade up against jig to fine tune the position of the blade. Use scrap piece to test cut, if all is well save this piece for later use in setting up the jig. Put in block of Corian back side out, cut side on top. Use piece of wood on side of Corian to act as a stop and push stick.

Use light pressure while bringing down blade. Use scrap piece of wood first to check cut and then mark the top so you know what side to cut. No fun cutting wrong side and watching the hole fall off, not that ive done that.

Using Table saw

On my saw I set the blade angle to 8 deg. I used the same jig but added a top and a back screwed on to hold things in place. After cutting let blade stop turning before you back up and remove stock.

Sand and buff as needed, sand off sharp edge as well. I use drill press with soft sanding disk covered with rag and Novus2.

Glue pen holder in hole, USE SMALL SMALL drop on side of holder, or bottom of hole. If you use more, the glue will come back out the hole and spread all around the outside of the pen holder. This is almost impossible to get rid of without scratching and buffing away gold plating, not that ive done that.

One PDT kit packaged, waiting to build

Buff pen and base.assemble.one whole family of PDTs...i done that !

Hope it helped and you have fun making these, I did. If you don’t have a saw let me know ill cut some for you, so you too can play.

pete