its_virgil

Member

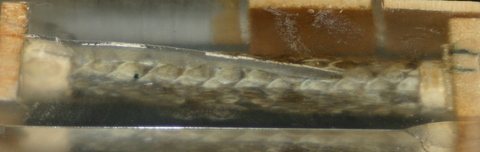

Here are some of the failures I've experienced on my journey to cast snake skin blanks. I went through my box of junk and found these which represent my most often produced failures.

Originally posted by laspringer

<br />Yes that is what I am talking about.

So do you think that a stable pressure is the

key to most of the problems?

Alan

Originally posted by Mudder

<br />I made my pot like the one posted here before. If I put 40 lbs of pressure in the pot is takes 2-3 hours to leak down to 30 psi. How long do you usually leave the thing under pressure?

Originally posted by its_virgil

<br />Scott,

I usually cast in the evening and let it "bake while I sleep" just like Mrs. Baird does her bread. It's always cured. But, if I cast at some other time, 4 hours is the minimum for me. But, I'm using only 3 drops of catalyst per ounce. More catalyst will be quicker but hotter and hotter is not better...I've actually cooked the skins right off the tubes. I'm also casting 16 ounces of resin at a time in a mold that is 4 x 7 x 1.

The pictures I posted were of some earlier casts before I "got in my groove" so to speak.

Do a good turn daily!

Don

Originally posted by Mudder

<br />I made my pot like the one posted here before. If I put 40 lbs of pressure in the pot is takes 2-3 hours to leak down to 30 psi. How long do you usually leave the thing under pressure?

Originally posted by johncrane

<br />DON when you said you had failures l did'nt think they could be this bad'obviously there wrecked.about the only thing you could save is the tubes.my thoughts on your good snakeskin pens now is much much higher.

There was no sign of any skin anywhere in the casting. I guess they just vaporized. Strange things have happened.

Originally posted by its_virgil

<br />There was no sign of any skin anywhere in the casting. [?quote]

[:0] Watch out, they've slithered away and are waiting to take their revenge when you least expect it.

Originally posted by Skye

<br />3 drops??? I didnt know if would even cure at that rate! I may have to try that. I think I was averaging closer to 8 with mine, if not 10. I cant remember off the top of my head. Regardless, I need to lower it. Luckily I havent had the time nor resin lately. Hopefully I can try again this weekend.