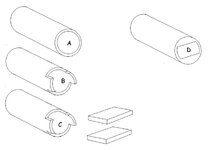

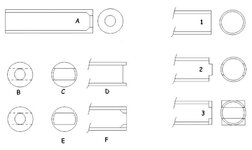

In this thread I was playing with the idea of having a cap with a Bayonet type connector instead of threads.

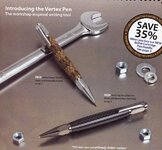

I'm pretty happy how it came out, but I think a bit more refinement would make it better. I don't like the transition from the sleeve to the nib.

Inside the cap are two little pins ( SS Hammer Rivets) They locate along the flats of the nib and then the cap pushes the spring loaded body sleeve further up the blank. The cap is then turned 90deg left or right, the spring then holds the pins in two matching indents hidden by the sleeve.

I wanted to have narrow grooves in the nib for the pins to go in, but I broke my last two small end mills. So I just used a big end mill and made the flats.

This pen is pretty small ( just smaller than a Baron ) The blue stuff is Bowling ball that I got from Jeff ( the Apprentice Scroller ) ages ago

Hope you like, and comments and criticisms welcomed:biggrin:

I'm pretty happy how it came out, but I think a bit more refinement would make it better. I don't like the transition from the sleeve to the nib.

Inside the cap are two little pins ( SS Hammer Rivets) They locate along the flats of the nib and then the cap pushes the spring loaded body sleeve further up the blank. The cap is then turned 90deg left or right, the spring then holds the pins in two matching indents hidden by the sleeve.

I wanted to have narrow grooves in the nib for the pins to go in, but I broke my last two small end mills. So I just used a big end mill and made the flats.

This pen is pretty small ( just smaller than a Baron ) The blue stuff is Bowling ball that I got from Jeff ( the Apprentice Scroller ) ages ago

Hope you like, and comments and criticisms welcomed:biggrin: